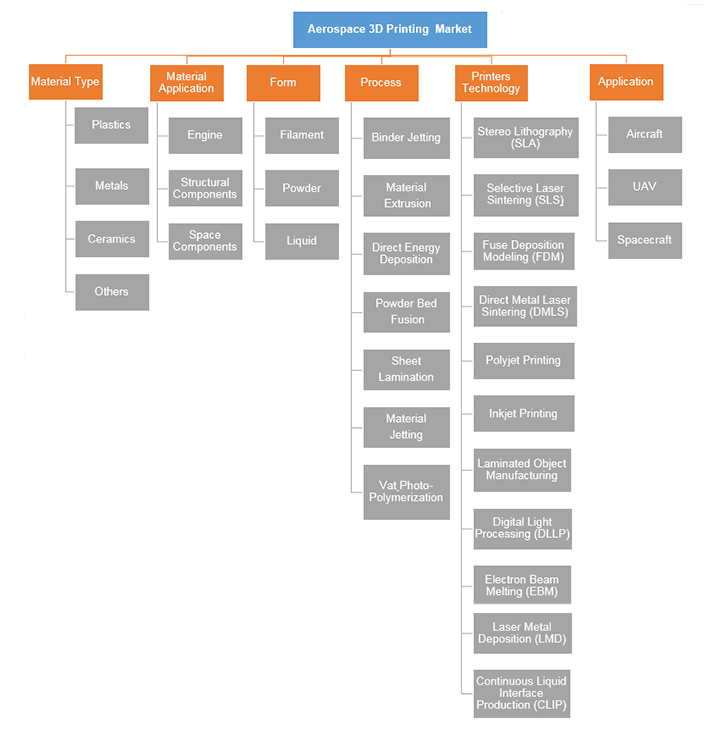

Aerospace 3D Printing Market by Material Type (Plastics, Metals, Ceramics, Others); by Material Application (Engine, Structural Components, Space Components); by Form (Filament, Powder, Liquid); by Process (Binder Jetting, Material Extrusion, Direct Energy Deposition, Powder Bed Fusion, Sheet Lamination, Material Jetting, Vat Photo-Polymerization); by Printers Technology (Stereo Lithography (SLA), Selective Laser Sintering (SLS), Fuse Deposition Modeling (FDM), Direct Metal Laser Sintering (DMLS), Polyjet Printing, Inkjet Printing, Laminated Object Manufacturing, Digital Light Processing (DLLP), Electron Beam Melting (EBM), Laser Metal Deposition (LMD), Continuous Liquid Interface Production (CLIP)); by Application (Aircraft, UAV, Spacecraft); by Regional Outlook (U.S., Rest of North America, France, UK, Germany, Spain, Italy, Rest of Europe, China, Japan, India, Southeast Asia, Rest of Asia Pacific, GCC Countries, Southern Africa, Rest of MEA, Brazil, Rest of Latin America) – Global Insights, Industry Trends, Price Trends, Growth, Size, Supply, Demand, Comparative Analysis, Competitive Market Share and Forecast, 2018-2026

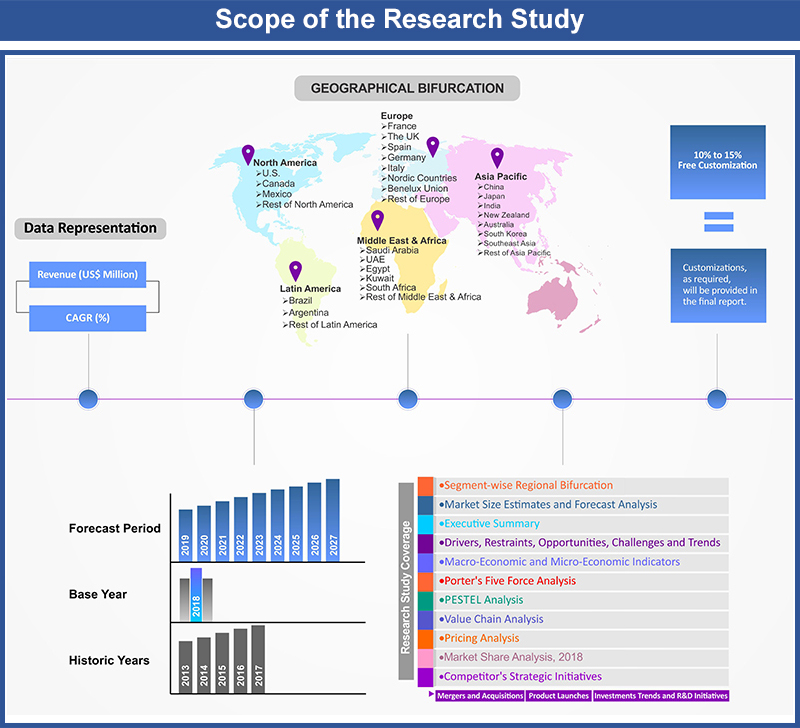

Industry Trends

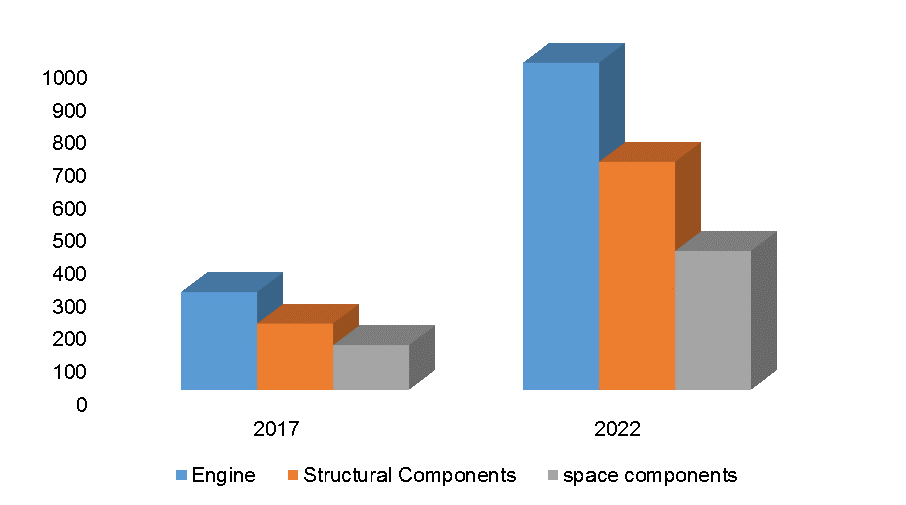

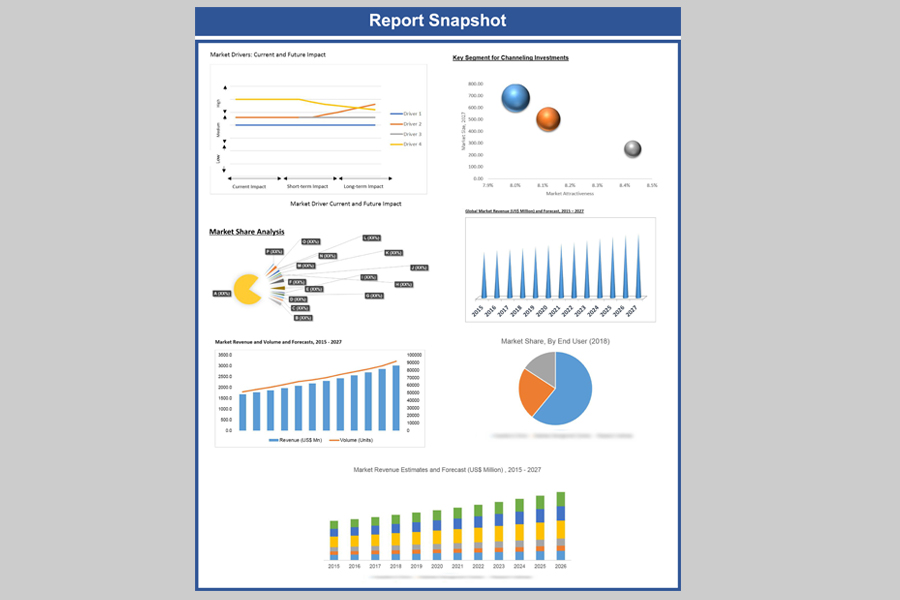

3D printing of parts is a new technology that has come up with the possibility to change the way enterprises build new products, including parts for defense and aerospace. This new manufacturing process is known as 3D printing or additive manufacturing. This innovation includes producing physical objects by printing one layer at any given moment, using special material deposition devices and computerized models. This present age 3D printing equipment has developed in a short span of time and is equipped for delivering complex components among various kinds of materials which includes aluminum, titanium, steel, and distinctive assortment of plastics. Along these lines, in view of its potential, 3D printing is gaining significance in different manufacturing and fabricating sectors. The Global Aerospace 3D Printing Market was valued at US$ 635.1 Mn in 2017 and is expected to reach US$ 2117.4 Mn by 2022.

Aerospace 3D Printing Market, by Material Application, 2017 & 2022 (USD Million)

The aerospace sector recognizes the unique competence of 3D printing and is pursuing ways to exploit these competencies. For example, Boeing is utilizing 3D printing to manufacture plastic interior parts out of nylon and polyetherimide for their test evaluation and prototype units. Boeing is utilizing 3D printing technology to swiftly manufacture tools for making composite parts. Additionally, Pratt & Whitney aerospace company is investing extensively in a state-of-the-art 3D manufacturing center in association with the University of Connecticut.

One of the essential drivers in the market is miniaturization of jet engines. 3D printing not just adds to the general weight reduction of the aircraft yet, in addition, empowers miniaturization of aircraft components. This, in turn, brings about fuel proficiency and a lower working expense. At the point when a gas turbine uses pulsed injection fuel rather than a constant injection, the pressure in both the compressor and ignition chamber increases. This enables the design of smaller and lighter compressor systems, which saves a lot of fuel. Increasing demand for lightweight aircraft air ship parts and components from the aerospace industry is driving the development of the aerospace 3D printing market.

Aerospace 3D Printing Market, by Material Application

On the basis of material application, the space components segment represented the maximum share of the market during 2015 and will keep on dominating the market for the following couple of years. One of the central point adding to the development of this segment is the increasing demand for production of lightweight and smaller engine components.

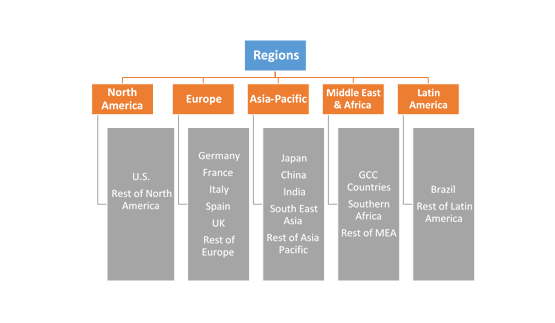

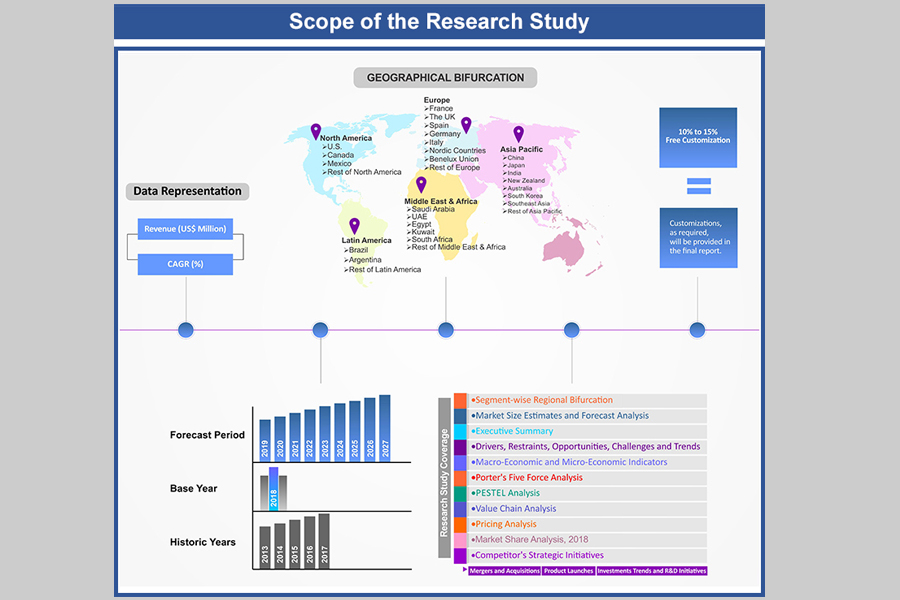

Aerospace 3D Printing Market, by Region

On the basis of geography, North America holds the largest share of the market. In this region, 3D printing technology is for the most part used as a part of major industrial manufacturing sectors, for example, defense, aviation, aerospace, healthcare and so on. Persistent technological advancements in areas, for example, science, infrastructure, industries, and so forth are boosting the market for North America. Additionally, the market for aerospace 3D printing in the Asia Pacific is likewise anticipated to develop at a prime rate amid the estimated time frame.

Competitive Market Share

The report provides both, subjective and quantitative research of the market, as well as integrates worthy insights into the rational scenario and favored development methods adopted by the key contenders. The report also offers extensive research on the key players in this market and detailed insights on the competitiveness of these players. The key business strategies such as M&A, affiliations, collaborations, and contracts adopted by the major players are also recognized and analyzed in the report. For each company, the report recognizes their manufacturing base, competitors, product type, application and specification, pricing, and gross margin.

Some of the primary players of Global Aerospace 3D Printing Market are Stratasys Ltd., 3D Systems Corporation, The ExOne Company, EOS GmbH, Arcam AB, Ultimaker B.V., and Materialise NV, Airbus B.V., Boeing, Rolls-Royce (U.K.), Pratt & Whitney, and GE Aviation, among others.

Aerospace 3D Printing Industry Background

1. Introduction

1.1. Market Scope

1.2. Market Segmentation

1.3. Methodology

1.4. Assumptions

2. Aerospace 3D Printing Market Snapshot

3. Executive Summary: Aerospace 3D Printing Market

4. Qualitative Analysis: Aerospace 3D Printing Market

4.1. Introduction

4.1.1. Product Definition

4.1.2. Industry Development

4.2. Market Dynamics

4.2.1. Drivers

4.2.2. Restraints

4.2.3. Opportunities

4.3.

Trends in Aerospace 3D

Printing Market

4.3.1. Innovations in Materials Used for 3D Printing.

5. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

5.1. Overview

5.1.1. Global Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts

5.2. Global Market Revenue (US$ Mn) and Forecasts, By Material Type

5.2.1. Plastics

5.2.1.1. Definition

5.2.1.2. Market Penetration

5.2.1.3. Market Revenue Expected to Increase by 2026

5.2.1.4. Compound Annual Growth Rate (CAGR)

5.2.2. Metals

5.2.2.1. Definition

5.2.2.2. Market Penetration

5.2.2.3. Market Revenue Expected to Increase by 2026

5.2.2.4. Compound Annual Growth Rate (CAGR)

5.2.3. Ceramics

5.2.3.1. Definition

5.2.3.2. Market Penetration

5.2.3.3. Market Revenue Expected to Increase by 2026

5.2.3.4. Compound Annual Growth Rate (CAGR)

5.2.4. Others

5.2.4.1. Definition

5.2.4.2. Market Penetration

5.2.4.3. Market Revenue Expected to Increase by 2026

5.2.4.4. Compound Annual Growth Rate (CAGR)

5.3. Key Segment for Channeling Investments

5.3.1. By Material Type

6. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

6.1. Overview

6.2. Global Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

6.2.1. Engine

6.2.1.1. Definition

6.2.1.2. Market Penetration

6.2.1.3. Market Revenue Expected to Increase by 2026

6.2.1.4. Compound Annual Growth Rate (CAGR)

6.2.2. Structural Components

6.2.2.1. Definition

6.2.2.2. Market Penetration

6.2.2.3. Market Revenue Expected to Increase by 2026

6.2.2.4. Compound Annual Growth Rate (CAGR)

6.2.3. Space Components

6.2.3.1. Definition

6.2.3.2. Market Penetration

6.2.3.3. Market Revenue Expected to Increase by 2026

6.2.3.4. Compound Annual Growth Rate (CAGR)

6.3. Key Segment for Channeling Investments

6.3.1. By Material Application

7. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

7.1. Overview

7.2. Global Market Revenue (US$ Mn) and Forecasts, By Form

7.2.1. Filament

7.2.1.1. Definition

7.2.1.2. Market Penetration

7.2.1.3. Market Revenue Expected to Increase by 2026

7.2.1.4. Compound Annual Growth Rate (CAGR)

7.2.2. Powder

7.2.2.1. Definition

7.2.2.2. Market Penetration

7.2.2.3. Market Revenue Expected to Increase by 2026

7.2.2.4. Compound Annual Growth Rate (CAGR)

7.2.3. Liquid

7.2.3.1. Definition

7.2.3.2. Market Penetration

7.2.3.3. Market Revenue Expected to Increase by 2026

7.2.3.4. Compound Annual Growth Rate (CAGR)

7.3. Key Segment for Channeling Investments

7.3.1. By Form

8. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

8.1. Overview

8.2. Global Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

8.2.1. Binder jetting

8.2.1.1. Definition

8.2.1.2. Market Penetration

8.2.1.3. Market Revenue Expected to Increase by 2026

8.2.1.4. Compound Annual Growth Rate (CAGR)

8.2.2. Material extrusion

8.2.2.1. Definition

8.2.2.2. Market Penetration

8.2.2.3. Market Revenue Expected to Increase by 2026

8.2.2.4. Compound Annual Growth Rate (CAGR)

8.2.3. Direct energy deposition

8.2.3.1. Definition

8.2.3.2. Market Penetration

8.2.3.3. Market Revenue Expected to Increase by 2026

8.2.3.4. Compound Annual Growth Rate (CAGR)

8.2.4. Powder bed fusion

8.2.4.1. Definition

8.2.4.2. Market Penetration

8.2.4.3. Market Revenue Expected to Increase by 2026

8.2.4.4. Compound Annual Growth Rate (CAGR)

8.2.5. Sheet lamination

8.2.5.1. Definition

8.2.5.2. Market Penetration

8.2.5.3. Market Revenue Expected to Increase by 2026

8.2.5.4. Compound Annual Growth Rate (CAGR)

8.2.6. Material jetting

8.2.6.1. Definition

8.2.6.2. Market Penetration

8.2.6.3. Market Revenue Expected to Increase by 2026

8.2.6.4. Compound Annual Growth Rate (CAGR)

8.2.7. Vat photo-polymerization

8.2.7.1. Definition

8.2.7.2. Market Penetration

8.2.7.3. Market Revenue Expected to Increase by 2026

8.2.7.4. Compound Annual Growth Rate (CAGR)

8.3. Key Segment for Channeling Investments

8.3.1. By Process

9. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

9.1. Overview

9.2. Global Aerospace 3D Printing Market Revenue (US$ Mn) and Forecasts,

By Printers Technology

9.2.1. Stereo lithography (SLA)

9.2.1.1. Definition

9.2.1.2. Market Penetration

9.2.1.3. Market Revenue Expected to Increase by 2026

9.2.1.4. Compound Annual Growth Rate (CAGR)

9.2.2. Selective Laser Sintering (SLS)

9.2.2.1. Definition

9.2.2.2. Market Penetration

9.2.2.3. Market Revenue Expected to Increase by 2026

9.2.2.4. Compound Annual Growth Rate (CAGR)

9.2.3. Fuse Deposition Modeling (FDM)

9.2.3.1. Definition

9.2.3.2. Market Penetration

9.2.3.3. Market Revenue Expected to Increase by 2026

9.2.3.4. Compound Annual Growth Rate (CAGR)

9.2.4. Direct Metal Laser Sintering (DMLS)

9.2.4.1. Definition

9.2.4.2. Market Penetration

9.2.4.3. Market Revenue Expected to Increase by 2026

9.2.4.4. Compound Annual Growth Rate (CAGR)

9.2.5. Polyjet Printing

9.2.5.1. Definition

9.2.5.2. Market Penetration

9.2.5.3. Market Revenue Expected to Increase by 2026

9.2.5.4. Compound Annual Growth Rate (CAGR)

9.2.6. Inkjet Printing

9.2.6.1. Definition

9.2.6.2. Market Penetration

9.2.6.3. Market Revenue Expected to Increase by 2026

9.2.6.4. Compound Annual Growth Rate (CAGR)

9.2.7. Laminated Object Manufacturing

9.2.7.1. Definition

9.2.7.2. Market Penetration

9.2.7.3. Market Revenue Expected to Increase by 2026

9.2.7.4. Compound Annual Growth Rate (CAGR)

9.2.8. Digital Light Processing (DLLP)

9.2.8.1. Definition

9.2.8.2. Market Penetration

9.2.8.3. Market Revenue Expected to Increase by 2026

9.2.8.4. Compound Annual Growth Rate (CAGR)

9.2.9. Electron Beam Melting (EBM)

9.2.9.1. Definition

9.2.9.2. Market Penetration

9.2.9.3. Market Revenue Expected to Increase by 2026

9.2.9.4. Compound Annual Growth Rate (CAGR)

9.2.10. Laser Metal Deposition (LMD)

9.2.10.1. Definition

9.2.10.2. Market Penetration

9.2.10.3. Market Revenue Expected to Increase by 2026

9.2.10.4. Compound Annual Growth Rate (CAGR)

9.2.11. Continuous Liquid Interface Production (CLIP)

9.2.11.1. Definition

9.2.11.2. Market Penetration

9.2.11.3. Market Revenue Expected to Increase by 2026

9.2.11.4. Compound Annual Growth Rate (CAGR)

9.3. Key Segment for Channeling Investments

9.3.1. By Printers Technology

10. Global Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

10.1. Overview

10.2. Global Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

10.2.1. Aircraft

10.2.1.1. Definition

10.2.1.2. Market Penetration

10.2.1.3. Market Revenue Expected to Increase by 2026

10.2.1.4. Compound Annual Growth Rate (CAGR)

10.2.2. UAV

10.2.2.1. Definition

10.2.2.2. Market Penetration

10.2.2.3. Market Revenue Expected to Increase by 2026

10.2.2.4. Compound Annual Growth Rate (CAGR)

10.2.3. Spacecraft

10.2.3.1. Definition

10.2.3.2. Market Penetration

10.2.3.3. Market Revenue Expected to Increase by 2026

10.2.3.4. Compound Annual Growth Rate (CAGR)

10.3. Key Segment for Channeling Investments

10.3.1. By Application

11. North America Aerospace 3D Printing Market Analysis and

Forecasts, 2018 – 2026

11.1. Overview

11.1.1. North America Market Revenue (US$ Mn)

11.2. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

11.2.1. Plastics

11.2.2. Metals

11.2.3. Ceramics

11.2.4. Others

11.3. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

11.3.1. Engine

11.3.2. Structural Components

11.3.3. Space Components

11.4. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

11.4.1. Filament

11.4.2. Powder

11.4.3. Liquid

11.5. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

11.5.1. Binder jetting

11.5.2. Material extrusion

11.5.3. Direct energy deposition

11.5.4. Powder bed fusion

11.5.5. Sheet lamination

11.5.6. Material jetting

11.5.7. Vat photo-polymerization

11.6. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

11.6.1. Stereo lithography (SLA)

11.6.2. Selective Laser Sintering (SLS)

11.6.3. Fuse Deposition Modeling (FDM)

11.6.4. Direct Metal Laser Sintering (DMLS)

11.6.5. Polyjet Printing

11.6.6. Inkjet Printing

11.6.7. Laminated Object Manufacturing

11.6.8. Digital Light Processing (DLLP)

11.6.9. Electron Beam Melting (EBM)

11.6.10. Laser Metal Deposition (LMD)

11.6.11. Continuous Liquid Interface Production (CLIP)

11.7. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

11.7.1. Aircraft

11.7.2. UAV

11.7.3. Spacecraft

11.8. North America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Country

11.8.1. U.S.

11.8.1.1. U.S. Market Revenue (US$ Mn) and Forecasts, By Material Type

11.8.1.1.1. Plastics

11.8.1.1.2. Metals

11.8.1.1.3. Ceramics

11.8.1.1.4. Others

11.8.1.2. U.S. Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

11.8.1.2.1. Engine

11.8.1.2.2. Structural Components

11.8.1.2.3. Space Components

11.8.1.3. U.S. Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

11.8.1.3.1. Filament

11.8.1.3.2. Powder

11.8.1.3.3. Liquid

11.8.1.4. U.S. Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

11.8.1.4.1. Binder jetting

11.8.1.4.2. Material extrusion

11.8.1.4.3. Direct energy deposition

11.8.1.4.4. Powder bed fusion

11.8.1.4.5. Sheet lamination

11.8.1.4.6. Material jetting

11.8.1.4.7. Vat photo-polymerization

11.8.1.5. U.S. Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

11.8.1.5.1. Stereo lithography (SLA)

11.8.1.5.2. Selective Laser Sintering (SLS)

11.8.1.5.3. Fuse Deposition Modeling (FDM)

11.8.1.5.4. Direct Metal Laser Sintering (DMLS)

11.8.1.5.5. Polyjet Printing

11.8.1.5.6. Inkjet Printing

11.8.1.5.7. Laminated Object Manufacturing

11.8.1.5.8. Digital Light Processing (DLLP)

11.8.1.5.9. Electron Beam Melting (EBM)

11.8.1.5.10. Laser Metal Deposition (LMD)

11.8.1.5.11. Continuous Liquid Interface Production (CLIP)

11.8.1.6. U.S. Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

11.8.1.6.1. Aircraft

11.8.1.6.2. UAV

11.8.1.6.3. Spacecraft

11.8.2. Rest of North America

11.8.2.1. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Type

11.8.2.1.1. Plastics

11.8.2.1.2. Metals

11.8.2.1.3. Ceramics

11.8.2.1.4. Others

11.8.2.2. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Application

11.8.2.2.1. Engine

11.8.2.2.2. Structural Components

11.8.2.2.3. Space Components

11.8.2.3. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Form

11.8.2.3.1. Filament

11.8.2.3.2. Powder

11.8.2.3.3. Liquid

11.8.2.4. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Process

11.8.2.4.1. Binder jetting

11.8.2.4.2. Material extrusion

11.8.2.4.3. Direct energy deposition

11.8.2.4.4. Powder bed fusion

11.8.2.4.5. Sheet lamination

11.8.2.4.6. Material jetting

11.8.2.4.7. Vat photo-polymerization

11.8.2.5. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Printers Technology

11.8.2.5.1. Stereo lithography (SLA)

11.8.2.5.2. Selective Laser Sintering (SLS)

11.8.2.5.3. Fuse Deposition Modeling (FDM)

11.8.2.5.4. Direct Metal Laser Sintering (DMLS)

11.8.2.5.5. Polyjet Printing

11.8.2.5.6. Inkjet Printing

11.8.2.5.7. Laminated Object Manufacturing

11.8.2.5.8. Digital Light Processing (DLLP)

11.8.2.5.9. Electron Beam Melting (EBM)

11.8.2.5.10. Laser Metal Deposition (LMD)

11.8.2.5.11. Continuous Liquid Interface Production (CLIP)

11.8.2.6. Rest of North America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Application

11.8.2.6.1. Aircraft

11.8.2.6.2. UAV

11.8.2.6.3. Spacecraft

11.9. Key Segment for Channeling Investments

11.9.1. By Country

11.9.2. By Material Type

11.9.3. By Material Application

11.9.4. By Form

11.9.5. By Process

11.9.6. By Printers Technology

11.9.7. By Application

12. Europe Aerospace 3D Printing Market Analysis and Forecasts,

2018 – 2026

12.1. Overview

12.1.1. Europe Market Revenue (US$ Mn)

12.2. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

12.2.1. Plastics

12.2.2. Metals

12.2.3. Ceramics

12.2.4. Others

12.3. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.3.1. Engine

12.3.2. Structural Components

12.3.3. Space Components

12.4. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.4.1. Filament

12.4.2. Powder

12.4.3. Liquid

12.5. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

12.5.1. Binder jetting

12.5.2. Material extrusion

12.5.3. Direct energy deposition

12.5.4. Powder bed fusion

12.5.5. Sheet lamination

12.5.6. Material jetting

12.5.7. Vat photo-polymerization

12.6. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.6.1. Stereo lithography (SLA)

12.6.2. Selective Laser Sintering (SLS)

12.6.3. Fuse Deposition Modeling (FDM)

12.6.4. Direct Metal Laser Sintering (DMLS)

12.6.5. Polyjet Printing

12.6.6. Inkjet Printing

12.6.7. Laminated Object Manufacturing

12.6.8. Digital Light Processing (DLLP)

12.6.9. Electron Beam Melting (EBM)

12.6.10. Laser Metal Deposition (LMD)

12.6.11. Continuous Liquid Interface

Production (CLIP)

12.7. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.7.1. Aircraft

12.7.2. UAV

12.7.3. Spacecraft

12.8. Europe Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Country

12.8.1. France

12.8.1.1. France Market Revenue (US$ Mn) and Forecasts, By Material Type

12.8.1.1.1. Plastics

12.8.1.1.2. Metals

12.8.1.1.3. Ceramics

12.8.1.1.4. Others

12.8.1.2. France Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.8.1.2.1. Engine

12.8.1.2.2. Structural Components

12.8.1.2.3. Space Components

12.8.1.3. France Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.8.1.3.1. Filament

12.8.1.3.2. Powder

12.8.1.3.3. Liquid

12.8.1.4. France Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

12.8.1.4.1. Binder jetting

12.8.1.4.2. Material extrusion

12.8.1.4.3. Direct energy deposition

12.8.1.4.4. Powder bed fusion

12.8.1.4.5. Sheet lamination

12.8.1.4.6. Material jetting

12.8.1.4.7. Vat photo-polymerization

12.8.1.5. France Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.8.1.5.1. Stereo lithography (SLA)

12.8.1.5.2. Selective Laser Sintering (SLS)

12.8.1.5.3. Fuse Deposition Modeling (FDM)

12.8.1.5.4. Direct Metal Laser Sintering (DMLS)

12.8.1.5.5. Polyjet Printing

12.8.1.5.6. Inkjet Printing

12.8.1.5.7. Laminated Object Manufacturing

12.8.1.5.8. Digital Light Processing (DLLP)

12.8.1.5.9. Electron Beam Melting (EBM)

12.8.1.5.10. Laser Metal Deposition (LMD)

12.8.1.5.11. Continuous Liquid Interface Production (CLIP)

12.8.1.6. France Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.8.1.6.1. Aircraft

12.8.1.6.2. UAV

12.8.1.6.3. Spacecraft

12.8.2. The UK

12.8.2.1. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

12.8.2.1.1. Plastics

12.8.2.1.2. Metals

12.8.2.1.3. Ceramics

12.8.2.1.4. Others

12.8.2.2. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.8.2.2.1. Engine

12.8.2.2.2. Structural Components

12.8.2.2.3. Space Components

12.8.2.3. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.8.2.3.1. Filament

12.8.2.3.2. Powder

12.8.2.3.3. Liquid

12.8.2.4. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

12.8.2.4.1. Binder jetting

12.8.2.4.2. Material extrusion

12.8.2.4.3. Direct energy deposition

12.8.2.4.4. Powder bed fusion

12.8.2.4.5. Sheet lamination

12.8.2.4.6. Material jetting

12.8.2.4.7. Vat photo-polymerization

12.8.2.5. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.8.2.5.1. Stereo lithography (SLA)

12.8.2.5.2. Selective Laser Sintering (SLS)

12.8.2.5.3. Fuse Deposition Modeling (FDM)

12.8.2.5.4. Direct Metal Laser Sintering (DMLS)

12.8.2.5.5. Polyjet Printing

12.8.2.5.6. Inkjet Printing

12.8.2.5.7. Laminated Object Manufacturing

12.8.2.5.8. Digital Light Processing (DLLP)

12.8.2.5.9. Electron Beam Melting (EBM)

12.8.2.5.10. Laser Metal Deposition (LMD)

12.8.2.5.11. Continuous Liquid Interface Production (CLIP)

12.8.2.6. The UK Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.8.2.6.1. Aircraft

12.8.2.6.2. UAV

12.8.2.6.3. Spacecraft

12.8.3. Spain

12.8.3.1. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

12.8.3.1.1. Plastics

12.8.3.1.2. Metals

12.8.3.1.3. Ceramics

12.8.3.1.4. Others

12.8.3.2. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.8.3.2.1. Engine

12.8.3.2.2. Structural Components

12.8.3.2.3. Space Components

12.8.3.3. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.8.3.3.1. Filament

12.8.3.3.2. Powder

12.8.3.3.3. Liquid

12.8.3.4. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

12.8.3.4.1. Binder jetting

12.8.3.4.2. Material extrusion

12.8.3.4.3. Direct energy deposition

12.8.3.4.4. Powder bed fusion

12.8.3.4.5. Sheet lamination

12.8.3.4.6. Material jetting

12.8.3.4.7. Vat photo-polymerization

12.8.3.5. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.8.3.5.1. Stereo lithography (SLA)

12.8.3.5.2. Selective Laser Sintering (SLS)

12.8.3.5.3. Fuse Deposition Modeling (FDM)

12.8.3.5.4. Direct Metal Laser Sintering (DMLS)

12.8.3.5.5. Polyjet Printing

12.8.3.5.6. Inkjet Printing

12.8.3.5.7. Laminated Object Manufacturing

12.8.3.5.8. Digital Light Processing (DLLP)

12.8.3.5.9. Electron Beam Melting (EBM)

12.8.3.5.10. Laser Metal Deposition (LMD)

12.8.3.5.11. Continuous Liquid Interface Production (CLIP)

12.8.3.6. Spain Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.8.3.6.1. Aircraft

12.8.3.6.2. UAV

12.8.3.6.3. Spacecraft

12.8.4. Germany

12.8.4.1. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

12.8.4.1.1. Plastics

12.8.4.1.2. Metals

12.8.4.1.3. Ceramics

12.8.4.1.4. Others

12.8.4.2. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.8.4.2.1. Engine

12.8.4.2.2. Structural Components

12.8.4.2.3. Space Components

12.8.4.3. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.8.4.3.1. Filament

12.8.4.3.2. Powder

12.8.4.3.3. Liquid

12.8.4.4. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and Forecasts,

By Process

12.8.4.4.1. Binder jetting

12.8.4.4.2. Material extrusion

12.8.4.4.3. Direct energy deposition

12.8.4.4.4. Powder bed fusion

12.8.4.4.5. Sheet lamination

12.8.4.4.6. Material jetting

12.8.4.4.7. Vat photo-polymerization

12.8.4.5. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.8.4.5.1. Stereo lithography (SLA)

12.8.4.5.2. Selective Laser Sintering (SLS)

12.8.4.5.3. Fuse Deposition Modeling (FDM)

12.8.4.5.4. Direct Metal Laser Sintering (DMLS)

12.8.4.5.5. Polyjet Printing

12.8.4.5.6. Inkjet Printing

12.8.4.5.7. Laminated Object Manufacturing

12.8.4.5.8. Digital Light Processing (DLLP)

12.8.4.5.9. Electron Beam Melting (EBM)

12.8.4.5.10. Laser Metal Deposition (LMD)

12.8.4.5.11. Continuous Liquid Interface Production (CLIP)

12.8.4.6. Germany Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.8.4.6.1. Aircraft

12.8.4.6.2. UAV

12.8.4.6.3. Spacecraft

12.8.5. Italy

12.8.5.1. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

12.8.5.1.1. Plastics

12.8.5.1.2. Metals

12.8.5.1.3. Ceramics

12.8.5.1.4. Others

12.8.5.2. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

12.8.5.2.1. Engine

12.8.5.2.2. Structural Components

12.8.5.2.3. Space Components

12.8.5.3. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

12.8.5.3.1. Filament

12.8.5.3.2. Powder

12.8.5.3.3. Liquid

12.8.5.4. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

12.8.5.4.1. Binder jetting

12.8.5.4.2. Material extrusion

12.8.5.4.3. Direct energy deposition

12.8.5.4.4. Powder bed fusion

12.8.5.4.5. Sheet lamination

12.8.5.4.6. Material jetting

12.8.5.4.7. Vat photo-polymerization

12.8.5.5. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

12.8.5.5.1. Stereo lithography (SLA)

12.8.5.5.2. Selective Laser Sintering (SLS)

12.8.5.5.3. Fuse Deposition Modeling (FDM)

12.8.5.5.4. Direct Metal Laser Sintering (DMLS)

12.8.5.5.5. Polyjet Printing

12.8.5.5.6. Inkjet Printing

12.8.5.5.7. Laminated Object Manufacturing

12.8.5.5.8. Digital Light Processing (DLLP)

12.8.5.5.9. Electron Beam Melting (EBM)

12.8.5.5.10. Laser Metal Deposition (LMD)

12.8.5.5.11. Continuous Liquid Interface Production (CLIP)

12.8.5.6. Italy Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

12.8.5.6.1. Aircraft

12.8.5.6.2. UAV

12.8.5.6.3. Spacecraft

12.8.6. Rest of Europe

12.8.6.1. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

12.8.6.1.1. Plastics

12.8.6.1.2. Metals

12.8.6.1.3. Ceramics

12.8.6.1.4. Others

12.8.6.2. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

12.8.6.2.1. Engine

12.8.6.2.2. Structural Components

12.8.6.2.3. Space Components

12.8.6.3. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

12.8.6.3.1. Filament

12.8.6.3.2. Powder

12.8.6.3.3. Liquid

12.8.6.4. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

12.8.6.4.1. Binder jetting

12.8.6.4.2. Material extrusion

12.8.6.4.3. Direct energy deposition

12.8.6.4.4. Powder bed fusion

12.8.6.4.5. Sheet lamination

12.8.6.4.6. Material jetting

12.8.6.4.7. Vat photo-polymerization

12.8.6.5. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

12.8.6.5.1. Stereo lithography (SLA)

12.8.6.5.2. Selective Laser Sintering (SLS)

12.8.6.5.3. Fuse Deposition Modeling (FDM)

12.8.6.5.4. Direct Metal Laser Sintering (DMLS)

12.8.6.5.5. Polyjet Printing

12.8.6.5.6. Inkjet Printing

12.8.6.5.7. Laminated Object Manufacturing

12.8.6.5.8. Digital Light Processing (DLLP)

12.8.6.5.9. Electron Beam Melting (EBM)

12.8.6.5.10.

Laser Metal Deposition (LMD)

12.8.6.5.11.

Continuous Liquid Interface

Production (CLIP)

12.8.6.6. Rest of Europe Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

12.8.6.6.1. Aircraft

12.8.6.6.2. UAV

12.8.6.6.3. Spacecraft

12.9. Key Segment for Channeling Investments

12.9.1. By Country

12.9.2. By Material Type

12.9.3. By Material Application

12.9.4. By Form

12.9.5. By Process

12.9.6. By Printers Technology

12.9.7. By Application

13. Asia Pacific Aerospace 3D Printing Market Analysis and

Forecasts, 2018 – 2026

13.1. Overview

13.1.1. Asia Pacific Market Revenue (US$ Mn)

13.2. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

13.2.1. Plastics

13.2.2. Metals

13.2.3. Ceramics

13.2.4. Others

13.3. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

13.3.1. Engine

13.3.2. Structural Components

13.3.3. Space Components

13.4. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

13.4.1. Filament

13.4.2. Powder

13.4.3. Liquid

13.5. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

13.5.1. Binder jetting

13.5.2. Material extrusion

13.5.3. Direct energy deposition

13.5.4. Powder bed fusion

13.5.5. Sheet lamination

13.5.6. Material jetting

13.5.7. Vat photo-polymerization

13.6. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

13.6.1. Stereo lithography (SLA)

13.6.2. Selective Laser Sintering (SLS)

13.6.3. Fuse Deposition Modeling (FDM)

13.6.4. Direct Metal Laser Sintering (DMLS)

13.6.5. Polyjet Printing

13.6.6. Inkjet Printing

13.6.7. Laminated Object Manufacturing

13.6.8. Digital Light Processing (DLLP)

13.6.9. Electron Beam Melting (EBM)

13.6.10. Laser Metal Deposition (LMD)

13.6.11. Continuous Liquid Interface Production (CLIP)

13.7. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

13.7.1. Aircraft

13.7.2. UAV

13.7.3. Spacecraft

13.8. Asia Pacific Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Country

13.8.1. China

13.8.1.1. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

13.8.1.1.1. Plastics

13.8.1.1.2. Metals

13.8.1.1.3. Ceramics

13.8.1.1.4. Others

13.8.1.2. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

13.8.1.2.1. Engine

13.8.1.2.2. Structural Components

13.8.1.2.3. Space Components

13.8.1.3. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

13.8.1.3.1. Filament

13.8.1.3.2. Powder

13.8.1.3.3. Liquid

13.8.1.4. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

13.8.1.4.1. Binder jetting

13.8.1.4.2. Material extrusion

13.8.1.4.3. Direct energy deposition

13.8.1.4.4. Powder bed fusion

13.8.1.4.5. Sheet lamination

13.8.1.4.6. Material jetting

13.8.1.4.7. Vat photo-polymerization

13.8.1.5. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

13.8.1.5.1. Stereo lithography (SLA)

13.8.1.5.2. Selective Laser Sintering (SLS)

13.8.1.5.3. Fuse Deposition Modeling (FDM)

13.8.1.5.4. Direct Metal Laser Sintering (DMLS)

13.8.1.5.5. Polyjet Printing

13.8.1.5.6. Inkjet Printing

13.8.1.5.7. Laminated Object Manufacturing

13.8.1.5.8. Digital Light Processing (DLLP)

13.8.1.5.9. Electron Beam Melting (EBM)

13.8.1.5.10. Laser Metal Deposition (LMD)

13.8.1.5.11. Continuous Liquid Interface Production (CLIP)

13.8.1.6. China Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

13.8.1.6.1. Aircraft

13.8.1.6.2. UAV

13.8.1.6.3. Spacecraft

13.8.2. Japan

13.8.2.1. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

13.8.2.1.1. Plastics

13.8.2.1.2. Metals

13.8.2.1.3. Ceramics

13.8.2.1.4. Others

13.8.2.2. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

13.8.2.2.1. Engine

13.8.2.2.2. Structural Components

13.8.2.2.3. Space Components

13.8.2.3. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

13.8.2.3.1. Filament

13.8.2.3.2. Powder

13.8.2.3.3. Liquid

13.8.2.4. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

13.8.2.4.1. Binder jetting

13.8.2.4.2. Material extrusion

13.8.2.4.3. Direct energy deposition

13.8.2.4.4. Powder bed fusion

13.8.2.4.5. Sheet lamination

13.8.2.4.6. Material jetting

13.8.2.4.7. Vat photo-polymerization

13.8.2.5. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

13.8.2.5.1. Stereo lithography (SLA)

13.8.2.5.2. Selective Laser Sintering (SLS)

13.8.2.5.3. Fuse Deposition Modeling (FDM)

13.8.2.5.4. Direct Metal Laser Sintering (DMLS)

13.8.2.5.5. Polyjet Printing

13.8.2.5.6. Inkjet Printing

13.8.2.5.7. Laminated Object Manufacturing

13.8.2.5.8. Digital Light Processing (DLLP)

13.8.2.5.9. Electron Beam Melting (EBM)

13.8.2.5.10. Laser Metal Deposition (LMD)

13.8.2.5.11. Continuous Liquid Interface Production (CLIP)

13.8.2.6. Japan Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

13.8.2.6.1. Aircraft

13.8.2.6.2. UAV

13.8.2.6.3. Spacecraft

13.8.3. India

13.8.3.1. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

13.8.3.1.1. Plastics

13.8.3.1.2. Metals

13.8.3.1.3. Ceramics

13.8.3.1.4. Others

13.8.3.2. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

13.8.3.2.1. Engine

13.8.3.2.2. Structural Components

13.8.3.2.3. Space Components

13.8.3.3. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

13.8.3.3.1. Filament

13.8.3.3.2. Powder

13.8.3.3.3. Liquid

13.8.3.4. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

13.8.3.4.1. Binder jetting

13.8.3.4.2. Material extrusion

13.8.3.4.3. Direct energy deposition

13.8.3.4.4. Powder bed fusion

13.8.3.4.5. Sheet lamination

13.8.3.4.6. Material jetting

13.8.3.4.7. Vat photo-polymerization

13.8.3.5. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

13.8.3.5.1. Stereo lithography (SLA)

13.8.3.5.2. Selective Laser Sintering (SLS)

13.8.3.5.3. Fuse Deposition Modeling (FDM)

13.8.3.5.4. Direct Metal Laser Sintering (DMLS)

13.8.3.5.5. Polyjet Printing

13.8.3.5.6. Inkjet Printing

13.8.3.5.7. Laminated Object Manufacturing

13.8.3.5.8. Digital Light Processing (DLLP)

13.8.3.5.9. Electron Beam Melting (EBM)

13.8.3.5.10.

Laser Metal Deposition (LMD)

13.8.3.5.11.

Continuous Liquid Interface

Production (CLIP)

13.8.3.6. India Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

13.8.3.6.1. Aircraft

13.8.3.6.2. UAV

13.8.3.6.3. Spacecraft

13.8.4. Southeast Asia

13.8.4.1. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

13.8.4.1.1. Plastics

13.8.4.1.2. Metals

13.8.4.1.3. Ceramics

13.8.4.1.4. Others

13.8.4.2. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

13.8.4.2.1. Engine

13.8.4.2.2. Structural Components

13.8.4.2.3. Space Components

13.8.4.3. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

13.8.4.3.1. Filament

13.8.4.3.2. Powder

13.8.4.3.3. Liquid

13.8.4.4. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

13.8.4.4.1. Binder jetting

13.8.4.4.2. Material extrusion

13.8.4.4.3. Direct energy deposition

13.8.4.4.4. Powder bed fusion

13.8.4.4.5. Sheet lamination

13.8.4.4.6. Material jetting

13.8.4.4.7. Vat photo-polymerization

13.8.4.5. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

13.8.4.5.1. Stereo lithography (SLA)

13.8.4.5.2. Selective Laser Sintering (SLS)

13.8.4.5.3. Fuse Deposition Modeling (FDM)

13.8.4.5.4. Direct Metal Laser Sintering (DMLS)

13.8.4.5.5. Polyjet Printing

13.8.4.5.6. Inkjet Printing

13.8.4.5.7. Laminated Object Manufacturing

13.8.4.5.8. Digital Light Processing (DLLP)

13.8.4.5.9. Electron Beam Melting (EBM)

13.8.4.5.10. Laser Metal Deposition (LMD)

13.8.4.5.11. Continuous Liquid Interface Production (CLIP)

13.8.4.6. Southeast Asia Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

13.8.4.6.1. Aircraft

13.8.4.6.2. UAV

13.8.4.6.3. Spacecraft

13.8.5. Rest of Asia Pacific

13.8.5.1. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Material Type

13.8.5.1.1. Plastics

13.8.5.1.2. Metals

13.8.5.1.3. Ceramics

13.8.5.1.4. Others

13.8.5.2. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Material Application

13.8.5.2.1. Engine

13.8.5.2.2. Structural Components

13.8.5.2.3. Space Components

13.8.5.3. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Form

13.8.5.3.1. Filament

13.8.5.3.2. Powder

13.8.5.3.3. Liquid

13.8.5.4. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Process

13.8.5.4.1. Binder jetting

13.8.5.4.2. Material extrusion

13.8.5.4.3. Direct energy deposition

13.8.5.4.4. Powder bed fusion

13.8.5.4.5. Sheet lamination

13.8.5.4.6. Material jetting

13.8.5.4.7. Vat photo-polymerization

13.8.5.5. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Printers Technology

13.8.5.5.1. Stereo lithography (SLA)

13.8.5.5.2. Selective Laser Sintering (SLS)

13.8.5.5.3. Fuse Deposition Modeling (FDM)

13.8.5.5.4. Direct Metal Laser Sintering (DMLS)

13.8.5.5.5. Polyjet Printing

13.8.5.5.6. Inkjet Printing

13.8.5.5.7. Laminated Object Manufacturing

13.8.5.5.8. Digital Light Processing (DLLP)

13.8.5.5.9. Electron Beam Melting (EBM)

13.8.5.5.10.

Laser Metal Deposition (LMD)

13.8.5.5.11.

Continuous Liquid Interface

Production (CLIP)

13.8.5.6. Rest of Asia Pacific Aerospace 3D Printing Market Revenue (US$

Mn) and Forecasts, By Application

13.8.5.6.1. Aircraft

13.8.5.6.2. UAV

13.8.5.6.3. Spacecraft

13.9. Key Segment for Channeling Investments

13.9.1. By Country

13.9.2. By Material Type

13.9.3. By Material Application

13.9.4. By Form

13.9.5. By Process

13.9.6. By Printers Technology

13.9.7. By Application

14. Middle East and Africa

Aerospace 3D Printing Market Analysis and Forecasts, 2018 – 2026

14.1. Overview

14.1.1. Middle East and Africa Market Revenue (US$ Mn)

14.2. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Type

14.2.1. Plastics

14.2.2. Metals

14.2.3. Ceramics

14.2.4. Others

14.3. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Application

14.3.1. Engine

14.3.2. Structural Components

14.3.3. Space Components

14.4. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Form

14.4.1. Filament

14.4.2. Powder

14.4.3. Liquid

14.5. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Process

14.5.1. Binder jetting

14.5.2. Material extrusion

14.5.3. Direct energy deposition

14.5.4. Powder bed fusion

14.5.5. Sheet lamination

14.5.6. Material jetting

14.5.7. Vat photo-polymerization

14.6. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Printers Technology

14.6.1. Stereo lithography (SLA)

14.6.2. Selective Laser Sintering (SLS)

14.6.3. Fuse Deposition Modeling (FDM)

14.6.4. Direct Metal Laser Sintering (DMLS)

14.6.5. Polyjet Printing

14.6.6. Inkjet Printing

14.6.7. Laminated Object Manufacturing

14.6.8. Digital Light Processing (DLLP)

14.6.9. Electron Beam Melting (EBM)

14.6.10.Laser

Metal Deposition (LMD)

14.6.11.Continuous

Liquid Interface Production (CLIP)

14.7. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Application

14.7.1. Aircraft

14.7.2. UAV

14.7.3. Spacecraft

14.8. Middle East and Africa Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Country

14.8.1. GCC Countries

14.8.1.1. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

14.8.1.1.1. Plastics

14.8.1.1.2. Metals

14.8.1.1.3. Ceramics

14.8.1.1.4. Others

14.8.1.2. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

14.8.1.2.1. Engine

14.8.1.2.2. Structural Components

14.8.1.2.3. Space Components

14.8.1.3. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

14.8.1.3.1. Filament

14.8.1.3.2. Powder

14.8.1.3.3. Liquid

14.8.1.4. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

14.8.1.4.1. Binder jetting

14.8.1.4.2. Material extrusion

14.8.1.4.3. Direct energy deposition

14.8.1.4.4. Powder bed fusion

14.8.1.4.5. Sheet lamination

14.8.1.4.6. Material jetting

14.8.1.4.7. Vat photo-polymerization

14.8.1.5. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

14.8.1.5.1. Stereo lithography (SLA)

14.8.1.5.2. Selective Laser Sintering (SLS)

14.8.1.5.3. Fuse Deposition Modeling (FDM)

14.8.1.5.4. Direct Metal Laser Sintering (DMLS)

14.8.1.5.5. Polyjet Printing

14.8.1.5.6. Inkjet Printing

14.8.1.5.7. Laminated Object Manufacturing

14.8.1.5.8. Digital Light Processing (DLLP)

14.8.1.5.9. Electron Beam Melting (EBM)

14.8.1.5.10. Laser Metal Deposition (LMD)

14.8.1.5.11. Continuous Liquid Interface Production (CLIP)

14.8.1.6. GCC Countries Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

14.8.1.6.1. Aircraft

14.8.1.6.2. UAV

14.8.1.6.3. Spacecraft

14.8.2. Southern Africa

14.8.2.1. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

14.8.2.1.1. Plastics

14.8.2.1.2. Metals

14.8.2.1.3. Ceramics

14.8.2.1.4. Others

14.8.2.2. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

14.8.2.2.1. Engine

14.8.2.2.2. Structural Components

14.8.2.2.3. Space Components

14.8.2.3. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

14.8.2.3.1. Filament

14.8.2.3.2. Powder

14.8.2.3.3. Liquid

14.8.2.4. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

14.8.2.4.1. Binder jetting

14.8.2.4.2. Material extrusion

14.8.2.4.3. Direct energy deposition

14.8.2.4.4. Powder bed fusion

14.8.2.4.5. Sheet lamination

14.8.2.4.6. Material jetting

14.8.2.4.7. Vat photo-polymerization

14.8.2.5. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

14.8.2.5.1. Stereo lithography (SLA)

14.8.2.5.2. Selective Laser Sintering (SLS)

14.8.2.5.3. Fuse Deposition Modeling (FDM)

14.8.2.5.4. Direct Metal Laser Sintering (DMLS)

14.8.2.5.5. Polyjet Printing

14.8.2.5.6. Inkjet Printing

14.8.2.5.7. Laminated Object Manufacturing

14.8.2.5.8. Digital Light Processing (DLLP)

14.8.2.5.9. Electron Beam Melting (EBM)

14.8.2.5.10. Laser Metal Deposition (LMD)

14.8.2.5.11. Continuous Liquid Interface Production (CLIP)

14.8.2.6. Southern Africa Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

14.8.2.6.1. Aircraft

14.8.2.6.2. UAV

14.8.2.6.3. Spacecraft

14.8.3. Rest of MEA

14.8.3.1. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Type

14.8.3.1.1. Plastics

14.8.3.1.2. Metals

14.8.3.1.3. Ceramics

14.8.3.1.4. Others

14.8.3.2. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

14.8.3.2.1. Engine

14.8.3.2.2. Structural Components

14.8.3.2.3. Space Components

14.8.3.3. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

14.8.3.3.1. Filament

14.8.3.3.2. Powder

14.8.3.3.3. Liquid

14.8.3.4. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

14.8.3.4.1. Binder jetting

14.8.3.4.2. Material extrusion

14.8.3.4.3. Direct energy deposition

14.8.3.4.4. Powder bed fusion

14.8.3.4.5. Sheet lamination

14.8.3.4.6. Material jetting

14.8.3.4.7. Vat photo-polymerization

14.8.3.5. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

14.8.3.5.1. Stereo lithography (SLA)

14.8.3.5.2. Selective Laser Sintering (SLS)

14.8.3.5.3. Fuse Deposition Modeling (FDM)

14.8.3.5.4. Direct Metal Laser Sintering (DMLS)

14.8.3.5.5. Polyjet Printing

14.8.3.5.6. Inkjet Printing

14.8.3.5.7. Laminated Object Manufacturing

14.8.3.5.8. Digital Light Processing (DLLP)

14.8.3.5.9. Electron Beam Melting (EBM)

14.8.3.5.10.

Laser Metal Deposition (LMD)

14.8.3.5.11.

Continuous Liquid Interface

Production (CLIP)

14.8.3.6. Rest of MEA Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

14.8.3.6.1. Aircraft

14.8.3.6.2. UAV

14.8.3.6.3. Spacecraft

14.9. Key Segment for Channeling Investments

14.9.1. By Country

14.9.2. By Material Type

14.9.3. By Material Application

14.9.4. By Form

14.9.5. By Process

14.9.6. By Printers Technology

14.9.7. By Application

15. Latin America Aerospace 3D Printing Market Analysis and

Forecasts, 2018 – 2026

15.1. Overview

15.1.1. Latin America Market Revenue (US$ Mn)

15.2. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Type

15.2.1. Plastics

15.2.2. Metals

15.2.3. Ceramics

15.2.4. Others

15.3. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Material Application

15.3.1. Engine

15.3.2. Structural Components

15.3.3. Space Components

15.4. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Form

15.4.1. Filament

15.4.2. Powder

15.4.3. Liquid

15.5. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Process

15.5.1. Binder jetting

15.5.2. Material extrusion

15.5.3. Direct energy deposition

15.5.4. Powder bed fusion

15.5.5. Sheet lamination

15.5.6. Material jetting

15.5.7. Vat photo-polymerization

15.6. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Printers Technology

15.6.1. Stereo lithography (SLA)

15.6.2. Selective Laser Sintering (SLS)

15.6.3. Fuse Deposition Modeling (FDM)

15.6.4. Direct Metal Laser Sintering (DMLS)

15.6.5. Polyjet Printing

15.6.6. Inkjet Printing

15.6.7. Laminated Object Manufacturing

15.6.8. Digital Light Processing (DLLP)

15.6.9. Electron Beam Melting (EBM)

15.6.10. Laser Metal Deposition (LMD)

15.6.11. Continuous Liquid Interface Production (CLIP)

15.7. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Application

15.7.1. Aircraft

15.7.2. UAV

15.7.3. Spacecraft

15.8. Latin America Aerospace 3D Printing Market Revenue (US$ Mn)

and Forecasts, By Country

15.8.1. Brazil

15.8.1.1. Brazil Market Revenue (US$ Mn) and Forecasts, By Material Type

15.8.1.1.1. Plastics

15.8.1.1.2. Metals

15.8.1.1.3. Ceramics

15.8.1.1.4. Others

15.8.1.2. Brazil Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Material Application

15.8.1.2.1. Engine

15.8.1.2.2. Structural Components

15.8.1.2.3. Space Components

15.8.1.3. Brazil Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Form

15.8.1.3.1. Filament

15.8.1.3.2. Powder

15.8.1.3.3. Liquid

15.8.1.4. Brazil Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Process

15.8.1.4.1. Binder jetting

15.8.1.4.2. Material extrusion

15.8.1.4.3. Direct energy deposition

15.8.1.4.4. Powder bed fusion

15.8.1.4.5. Sheet lamination

15.8.1.4.6. Material jetting

15.8.1.4.7. Vat photo-polymerization

15.8.1.5. Brazil Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Printers Technology

15.8.1.5.1. Stereo lithography (SLA)

15.8.1.5.2. Selective Laser Sintering (SLS)

15.8.1.5.3. Fuse Deposition Modeling (FDM)

15.8.1.5.4. Direct Metal Laser Sintering (DMLS)

15.8.1.5.5. Polyjet Printing

15.8.1.5.6. Inkjet Printing

15.8.1.5.7. Laminated Object Manufacturing

15.8.1.5.8. Digital Light Processing (DLLP)

15.8.1.5.9. Electron Beam Melting (EBM)

15.8.1.5.10. Laser Metal Deposition (LMD)

15.8.1.5.11. Continuous Liquid Interface Production (CLIP)

15.8.1.6. Brazil Aerospace 3D Printing Market Revenue (US$ Mn) and

Forecasts, By Application

15.8.1.6.1. Aircraft

15.8.1.6.2. UAV

15.8.1.6.3. Spacecraft

15.8.2. Rest of Latin America

15.8.2.1. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Type

15.8.2.1.1. Plastics

15.8.2.1.2. Metals

15.8.2.1.3. Ceramics

15.8.2.1.4. Others

15.8.2.2. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Material Application

15.8.2.2.1. Engine

15.8.2.2.2. Structural Components

15.8.2.2.3. Space Components

15.8.2.3. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Form

15.8.2.3.1. Filament

15.8.2.3.2. Powder

15.8.2.3.3. Liquid

15.8.2.4. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Process

15.8.2.4.1. Binder jetting

15.8.2.4.2. Material extrusion

15.8.2.4.3. Direct energy deposition

15.8.2.4.4. Powder bed fusion

15.8.2.4.5. Sheet lamination

15.8.2.4.6. Material jetting

15.8.2.4.7. Vat photo-polymerization

15.8.2.5. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Printers Technology

15.8.2.5.1. Stereo lithography (SLA)

15.8.2.5.2. Selective Laser Sintering (SLS)

15.8.2.5.3. Fuse Deposition Modeling (FDM)

15.8.2.5.4. Direct Metal Laser Sintering (DMLS)

15.8.2.5.5. Polyjet Printing

15.8.2.5.6. Inkjet Printing

15.8.2.5.7. Laminated Object Manufacturing

15.8.2.5.8. Digital Light Processing (DLLP)

15.8.2.5.9. Electron Beam Melting (EBM)

15.8.2.5.10.

Laser Metal Deposition (LMD)

15.8.2.5.11.

Continuous Liquid Interface

Production (CLIP)

15.8.2.6. Rest of Latin America Aerospace 3D Printing Market Revenue

(US$ Mn) and Forecasts, By Application

15.8.2.6.1. Aircraft

15.8.2.6.2. UAV

15.8.2.6.3. Spacecraft

15.9. Key Segment for Channeling Investments

15.9.1. By Country

15.9.2. By Material Type

15.9.3. By Material Application

15.9.4. By Form

15.9.5. By Process

15.9.6. By Printers Technology

15.9.7. By Application

16. Competitive Benchmarking

16.1. Player Positioning Analysis

16.2. Global Presence and Growth Strategies

17. Player Profiles

17.1. 3D Systems Corporation

17.1.1. Company Details

17.1.2. Company Overview

17.1.3. Product Offerings

17.1.4. Key Developments

17.1.5. Financial Analysis

17.1.6. SWOT Analysis

17.1.7. Business Strategies

17.2. AERIA Luxury Interiors

17.2.1. Company Details

17.2.2. Company Overview

17.2.3. Product Offerings

17.2.4. Key Developments

17.2.5. Financial Analysis

17.2.6. SWOT Analysis

17.2.7. Business Strategies

17.3. Aerojet Rocketdyne

17.3.1. Company Details

17.3.2. Company Overview

17.3.3. Product Offerings

17.3.4. Key Developments

17.3.5. Financial Analysis

17.3.6. SWOT Analysis

17.3.7. Business Strategies

17.4. Airbus

17.4.1. Company Details

17.4.2. Company Overview

17.4.3. Product Offerings

17.4.4. Key Developments

17.4.5. Financial Analysis

17.4.6. SWOT Analysis

17.4.7. Business Strategies

17.5. Arcam AB

17.5.1. Company Details

17.5.2. Company Overview

17.5.3. Product Offerings

17.5.4. Key Developments

17.5.5. Financial Analysis

17.5.6. SWOT Analysis

17.5.7. Business Strategies

17.6. Boeing

17.6.1. Company Details

17.6.2. Company Overview

17.6.3. Product Offerings

17.6.4. Key Developments

17.6.5. Financial Analysis

17.6.6. SWOT Analysis

17.6.7. Business Strategies

17.7. Envisiontec GmbH

17.7.1. Company Details

17.7.2. Company Overview

17.7.3. Product Offerings

17.7.4. Key Developments

17.7.5. Financial Analysis

17.7.6. SWOT Analysis

17.7.7. Business Strategies

17.8. EOS Gmbh

17.8.1. Company Details

17.8.2. Company Overview

17.8.3. Product Offerings

17.8.4. Key Developments

17.8.5. Financial Analysis

17.8.6. SWOT Analysis

17.8.7. Business Strategies

17.9. GE aviation

17.9.1. Company Details

17.9.2. Company Overview

17.9.3. Product Offerings

17.9.4. Key Developments

17.9.5. Financial Analysis

17.9.6. SWOT Analysis

17.9.7. Business Strategies

17.10. Hoganas AB

17.10.1. Company Details

17.10.2. Company Overview

17.10.3. Product Offerings

17.10.4. Key Developments

17.10.5. Financial Analysis

17.10.6. SWOT Analysis

17.10.7. Business Strategies

17.11. Honeywell International

17.11.1.

Company Details

17.11.2.

Company Overview

17.11.3.

Product Offerings

17.11.4.

Key Developments

17.11.5.

Financial Analysis

17.11.6.

SWOT Analysis

17.11.7.

Business Strategies

17.12. JBRND

17.12.1.

Company Details

17.12.2.

Company Overview

17.12.3.

Product Offerings

17.12.4.

Key Developments

17.12.5.

Financial Analysis

17.12.6.

SWOT Analysis

17.12.7.

Business Strategies

17.13. Materialise NV

17.13.1.

Company Details

17.13.2.

Company Overview

17.13.3.

Product Offerings

17.13.4.

Key Developments

17.13.5.

Financial Analysis

17.13.6.

SWOT Analysis

17.13.7.

Business Strategies

17.14. Moog

17.14.1.

Company Details

17.14.2.

Company Overview

17.14.3.

Product Offerings

17.14.4.

Key Developments

17.14.5.

Financial Analysis

17.14.6.

SWOT Analysis

17.14.7.

Business Strategies

17.15. MTU Aero Engines AG

17.15.1.

Company Details

17.15.2.

Company Overview

17.15.3.

Product Offerings

17.15.4.

Key Developments

17.15.5.

Financial Analysis

17.15.6.

SWOT Analysis

17.15.7.

Business Strategies

17.16. Norsk Titanium AS

17.16.1.

Company Details

17.16.2.

Company Overview

17.16.3.

Product Offerings

17.16.4.

Key Developments

17.16.5.

Financial Analysis

17.16.6.

SWOT Analysis

17.16.7.

Business Strategies

17.17. Organovo Holdings Inc

17.17.1.

Company Details

17.17.2.

Company Overview

17.17.3.

Product Offerings

17.17.4.

Key Developments

17.17.5.

Financial Analysis

17.17.6.

SWOT Analysis

17.17.7.

Business Strategies

17.18. Pratt & Whitney Aerospace Company

17.18.1.

Company Details

17.18.2.

Company Overview

17.18.3.

Product Offerings

17.18.4.

Key Developments

17.18.5.

Financial Analysis

17.18.6.

SWOT Analysis

17.18.7.

Business Strategies

17.19. Rolls-Royce

17.19.1.

Company Details

17.19.2.

Company Overview

17.19.3.

Product Offerings

17.19.4.

Key Developments

17.19.5.

Financial Analysis

17.19.6.

SWOT Analysis

17.19.7.

Business Strategies

17.20. Sandvik

17.20.1.

Company Details

17.20.2.

Company Overview

17.20.3.

Product Offerings

17.20.4.

Key Developments

17.20.5.

Financial Analysis

17.20.6.

SWOT Analysis

17.20.7.

Business Strategies

17.21. Solvay S.A.

17.21.1.

Company Details

17.21.2.

Company Overview

17.21.3.

Product Offerings

17.21.4.

Key Developments

17.21.5.

Financial Analysis

17.21.6.

SWOT Analysis

17.21.7.

Business Strategies

17.22. Stratasys Ltd.

17.22.1.

Company Details

17.22.2.

Company Overview

17.22.3.

Product Offerings

17.22.4.

Key Developments

17.22.5.

Financial Analysis

17.22.6.

SWOT Analysis

17.22.7.

Business Strategies

17.23. The Exone Company

17.23.1.

Company Details

17.23.2.

Company Overview

17.23.3.

Product Offerings

17.23.4.

Key Developments

17.23.5.

Financial Analysis

17.23.6.

SWOT Analysis

17.23.7.

Business Strategies

17.24. Ultimaker B.V.

17.24.1.

Company Details

17.24.2.

Company Overview

17.24.3.

Product Offerings

17.24.4.

Key Developments

17.24.5.

Financial Analysis

17.24.6.

SWOT Analysis

17.24.7.

Business Strategies

Note: This ToC is

tentative and can be changed according to the research study conducted during

the course of report completion.

At Absolute Markets Insights, we are engaged in building both global as well as country specific reports. As a result, the approach taken for deriving the estimation and forecast for a specific country is a bit unique and different in comparison to the global research studies. In this case, we not only study the concerned market factors & trends prevailing in a particular country (from secondary research) but we also tend to calculate the actual market size & forecast from the revenue generated from the market participants involved in manufacturing or distributing the any concerned product. These companies can also be service providers. For analyzing any country specifically, we do consider the growth factors prevailing under the states/cities/county for the same. For instance, if we are analyzing an industry specific to United States, we primarily need to study about the states present under the same(where the product/service has the highest growth). Similar analysis will be followed by other countries. Our scope of the report changes with different markets.

Our research study is mainly implement through a mix of both secondary and primary research. Various sources such as industry magazines, trade journals, and government websites and trade associations are reviewed for gathering precise data. Primary interviews are conducted to validate the market size derived from secondary research. Industry experts, major manufacturers and distributors are contacted for further validation purpose on the current market penetration and growth trends.

Prominent participants in our primary research process include:

- Key Opinion Leaders namely the CEOs, CSOs, VPs, purchasing managers, amongst others

- Research and development participants, distributors/suppliers and subject matter experts

Secondary Research includes data extracted from paid data sources:

- Reuters

- Factiva

- Bloomberg

- One Source

- Hoovers

Research Methodology

Key Inclusions

Reach to us

Call us on

+91-74002-42424

Drop us an email at

sales@absolutemarketsinsights.com

Why Absolute Markets Insights?

An effective strategy is the entity that influences a business to stand out of the crowd. An organization with a phenomenal strategy for success dependably has the edge over the rivals in the market. It offers the organizations a head start in planning their strategy. Absolute Market Insights is the new initiation in the industry that will furnish you with the lead your business needs. Absolute Market Insights is the best destination for your business intelligence and analytical solutions; essentially because our qualitative and quantitative sources of information are competent to give one-stop solutions. We inventively combine qualitative and quantitative research in accurate proportions to have the best report, which not only gives the most recent insights but also assists you to grow.