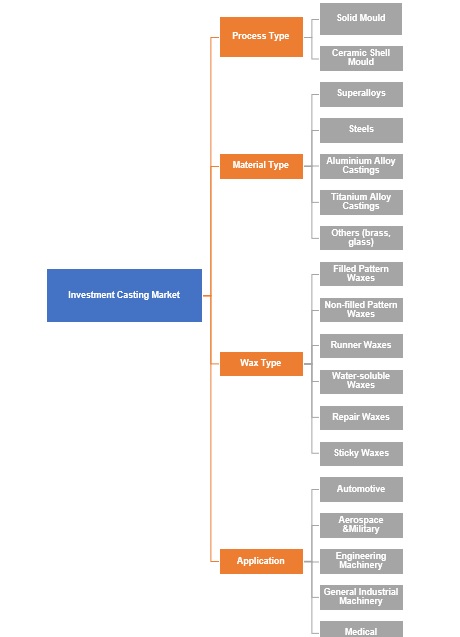

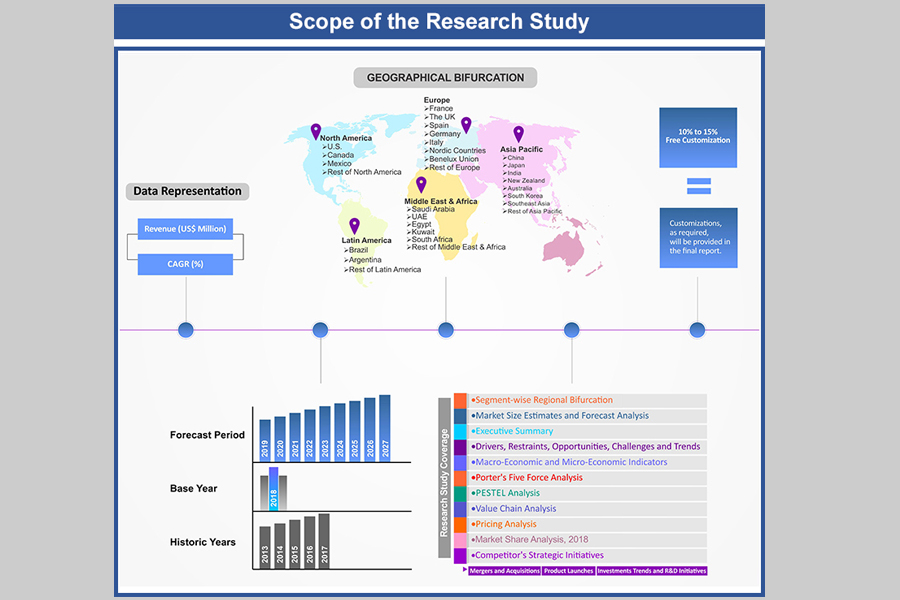

Investment Casting Market by Process Type (Solid Mould and Ceramic Shell Mould); by Material Type (Superalloys, Steels, Aluminium Alloy Castings, Titanium Alloy Castings and Others (brass, glass)); by Wax Type (Filled Pattern Waxes, Non-filled Pattern Waxes, Runner Waxes, Water-soluble Waxes, Repair Waxes and Sticky Waxes) by Application (Automotive, Aerospace &Military, Engineering Machinery, General Industrial Machinery and Medical); by Regional outlook (U.S., Rest of North America, France, UK, Germany, Spain, Italy, Rest of Europe, China, Japan, India, Southeast Asia, Rest of Asia Pacific, GCC Countries, Southern Africa, Rest of MEA, Brazil, Rest of Latin America) – Global Insights, Growth, Size, Comparative Analysis, Trends and Forecast, 2018-2026

Industry Trends

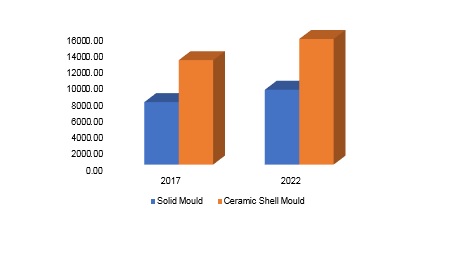

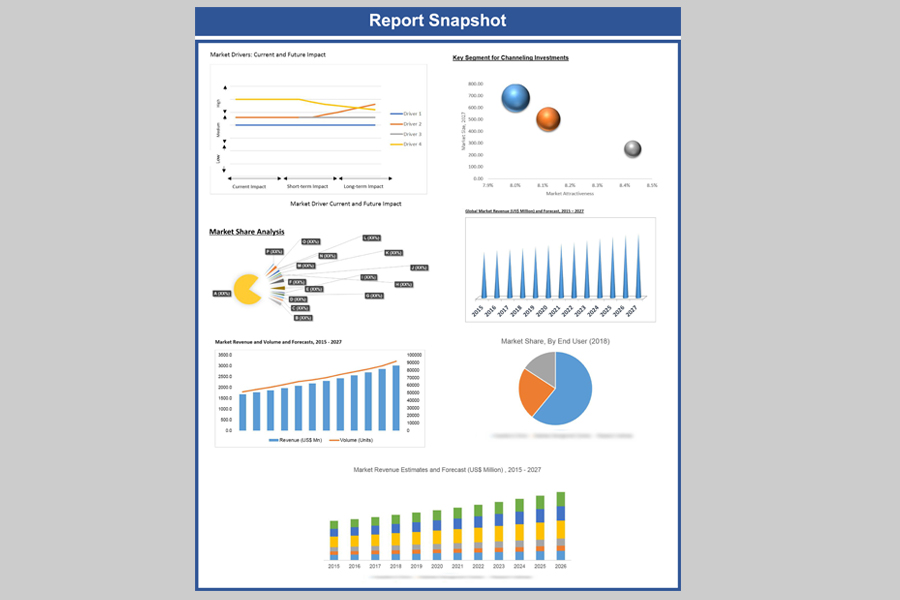

Investment casting is an industrial process based on lost-wax casting, which is one of the oldest known metal-forming techniques. In this, a ceramic mould is prepared by surrounding the ceramic material over the wax or plastic pattern. Investment casting is highly preferred in places with parts involving contoured surfaces, undercuts, other intricate shapes, places where machining is difficult or unfeasible. They are primarily used in sewing machines, firearms, surgical and dental devices, turbine blades, gear impeller, hand tools, cranks and levers. The global investment casting market was valued at US$ 20,343.3 Mn in 2017 and is expected to reach US$ 24,426.4 Mn by 2022. However, gradual growing demand in aerospace & military sector to make better product is accelerating the growth.

Investment Casting Market, By Process Type, 2018-2026 (USD Million)

Investment casting consists of two types of process such as solid mould and ceramic shell mould. These two processes vary each other mainly by the formation of the mould. In solid mould process the pattern is placed into a container and mould material poured around the pattern and allowed to solidify to make the solid block. Whereas, in case of ceramic shell mould, the pattern is immersed into ceramic slurry and after taking out from the slurry it is rotated to produce a uniform coating. However, ceramic shell mould is currently dominating the market owing to its easy usage.

Investment Casting Market, by Material Type

The material plays a vital role in final result as the different characteristic of these material are used to obtain various parts. However, super alloys are currently holding the maximum market share due to high usage in the aircraft engines. Increasing demand for high performance, lightweight materials in aerospace, automotive, industrial gas turbines (IGT) and industrial applications is expected to have a positive impact on super alloys market growth over the forecast period.

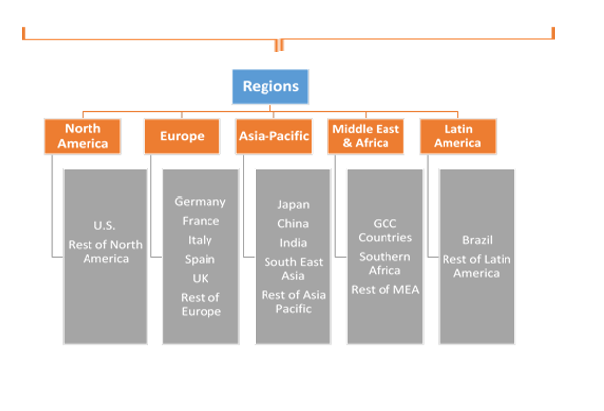

Investment Casting Market, by Region

Asia Pacific currently holds the maximum market share in the global investment casting market owing to increasing industrialization and development in this region. In the last four decades, a large number of foundries in developed countries have closed down due to high labor cost, production costs and raw material costs. Even global recession triggered the low demand of investment casting. Manufacturers are largely preferring to set up their production facilities in APAC region. This shift was majorly driven by rigid environmental stipulations and initiatives with regard to waste, energy, and environmental taxation by governments in Western countries. In APAC countries, raw materials are abundantly available, even though its quality is inferior sometimes with these they also have an added advantage of availability of cheap labor in these countries which hints the untapped potential of these markets. Owing to this driving factors many organizations have expanded their manufacturing operations across the globe, especially in the APAC region, to tap the potential of the rapidly growing market in countries such as China and India.

Competitive Market Share

The report provides both, qualitative and quantitative research of the market, as well as integrates worthy insights into the rational scenario and favored development methods adopted by the key contenders. The report also offers extensive research on the key players in this market and detailed insights on the competitiveness of these players. The key business strategies such as M&A, affiliations, collaborations, and contracts adopted by the major players are also recognized and analyzed in the report. For each company, the report recognizes their manufacturing base, competitors, product type, application and specification, pricing, and gross margin.

The investment casting market is fragmented since the market has giant players who are generating maximum market share. Some of the primary players of fragmented global investment casting market are ABB, Alcoa Corporation, Precision Castparts Corp, ThyssenKrupp AG, Amtek Group, Aristo Cast Corporation, Bharat Forge Ltd., CIREX, Doncasters Group Ltd, Georg Fischer Ltd., MetalTek International, Milwaukee Precision Casting, Inc., Nova Technocast, RLM Industries, Inc., Signicast, Solidscape Inc., The Anchor Danly Company, THOMPSON INVESTMENT CASTING and ZOLLERN GmbH & Co. KG.

Investment Casting Industry Background

1. Introduction

1.1.

Market Scope

1.2.

Market

Segmentation

1.3.

Methodology

1.4.

Assumptions

2. Investment

Casting Market Snapshot

3. Executive

Summary: Investment Casting Market

4. Qualitative

Analysis: Investment Casting Market

4.1.

Introduction

4.1.1.

Product

Definition

4.1.2.

Industry

Development

4.2.

Market Dynamics

4.2.1.

Drivers

4.2.2.

Restraints

4.2.3.

Opportunities

4.3.

Trends in

Investment Casting Market

4.4. Value Chain Analysis: Investment Casting Market

5. Global

Investment Casting Market Analysis and Forecasts, 2018 – 2026

5.1.

Overview

5.1.1.

Global

Investment Casting Market Revenue (US$ Mn) and Forecasts

5.2.

Global

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

5.2.1.

Solid Mould

5.2.1.1.

Definition

5.2.1.2.

Market

Penetration

5.2.1.3.

Market Revenue

Expected to Increase by 2026

5.2.1.4.

Compound Annual

Growth Rate (CAGR)

5.2.2.

Ceramic Shell

Mould

5.2.2.1.

Definition

5.2.2.2.

Market

Penetration

5.2.2.3.

Market Revenue

Expected to Increase by 2026

5.2.2.4.

Compound Annual

Growth Rate (CAGR)

5.3.

Key Segment for

Channeling Investments

5.3.1.

By Process Type

6. Global

Investment Casting Market Analysis and Forecasts, 2018 – 2026

6.1.

Overview

6.2.

Global

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

6.2.1.

Superalloys

6.2.1.1.

Definition

6.2.1.2.

Market

Penetration

6.2.1.3.

Market Revenue

Expected to Increase by 2026

6.2.1.4.

Compound Annual

Growth Rate (CAGR)

6.2.2.

Steels

6.2.2.1.

Definition

6.2.2.2.

Market

Penetration

6.2.2.3.

Market Revenue

Expected to Increase by 2026

6.2.2.4.

Compound Annual

Growth Rate (CAGR)

6.2.3.

Aluminium Alloy

Castings

6.2.3.1.

Definition

6.2.3.2.

Market

Penetration

6.2.3.3.

Market Revenue

Expected to Increase by 2026

6.2.3.4.

Compound Annual

Growth Rate (CAGR)

6.2.4.

Titanium Alloy

Castings

6.2.4.1.

Definition

6.2.4.2.

Market

Penetration

6.2.4.3.

Market Revenue

Expected to Increase by 2026

6.2.4.4.

Compound Annual

Growth Rate (CAGR)

6.2.5.

Others (brass,

glass)

6.2.5.1.

Definition

6.2.5.2.

Market

Penetration

6.2.5.3.

Market Revenue

Expected to Increase by 2026

6.2.5.4.

Compound Annual

Growth Rate (CAGR)

6.3.

Key Segment for

Channeling Investments

6.3.1.

By Material

Type

7. Global

Investment Casting Market Analysis and Forecasts, 2018 – 2026

7.1.

Overview

7.2.

Global Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

7.2.1.

Filled Pattern

Waxes

7.2.1.1.

Definition

7.2.1.2.

Market

Penetration

7.2.1.3.

Market Revenue

Expected to Increase by 2026

7.2.1.4.

Compound Annual

Growth Rate (CAGR)

7.2.2.

Non-filled

Pattern Waxes

7.2.2.1.

Definition

7.2.2.2.

Market

Penetration

7.2.2.3.

Market Revenue

Expected to Increase by 2026

7.2.2.4.

Compound Annual

Growth Rate (CAGR)

7.2.3.

Runner Waxes

7.2.3.1.

Definition

7.2.3.2.

Market

Penetration

7.2.3.3.

Market Revenue

Expected to Increase by 2026

7.2.3.4.

Compound Annual

Growth Rate (CAGR)

7.2.4.

Water-soluble

Waxes

7.2.4.1.

Definition

7.2.4.2.

Market

Penetration

7.2.4.3.

Market Revenue

Expected to Increase by 2026

7.2.4.4.

Compound Annual

Growth Rate (CAGR)

7.2.5.

Repair Waxes

7.2.5.1.

Definition

7.2.5.2.

Market

Penetration

7.2.5.3.

Market Revenue

Expected to Increase by 2026

7.2.5.4.

Compound Annual

Growth Rate (CAGR)

7.2.6.

Sticky Waxes

7.2.6.1.

Definition

7.2.6.2.

Market

Penetration

7.2.6.3.

Market Revenue Expected

to Increase by 2026

7.2.6.4.

Compound Annual

Growth Rate (CAGR)

7.3.

Key Segment for

Channeling Investments

7.3.1.

By Wax Type

8. Global

Investment Casting Market Analysis and Forecasts, 2018 – 2026

8.1.

Overview

8.2.

Global

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

8.2.1.

Automotive

8.2.1.1.

Definition

8.2.1.2.

Market

Penetration

8.2.1.3.

Market Revenue

Expected to Increase by 2026

8.2.1.4.

Compound Annual

Growth Rate (CAGR)

8.2.2.

Aerospace and

Military

8.2.2.1.

Definition

8.2.2.2.

Market

Penetration

8.2.2.3.

Market Revenue

Expected to Increase by 2026

8.2.2.4.

Compound Annual

Growth Rate (CAGR)

8.2.3.

Engineering

Machinery

8.2.3.1.

Definition

8.2.3.2.

Market

Penetration

8.2.3.3.

Market Revenue

Expected to Increase by 2026

8.2.3.4.

Compound Annual

Growth Rate (CAGR)

8.2.4.

General

Industrial Machinery

8.2.4.1.

Definition

8.2.4.2.

Market

Penetration

8.2.4.3.

Market Revenue

Expected to Increase by 2026

8.2.4.4.

Compound Annual

Growth Rate (CAGR)

8.2.5.

Medical

8.2.5.1.

Definition

8.2.5.2.

Market

Penetration

8.2.5.3.

Market Revenue

Expected to Increase by 2026

8.2.5.4.

Compound Annual

Growth Rate (CAGR)

8.3.

Key Segment for

Channeling Investments

8.3.1.

By Application

9. North

America Investment Casting Market Analysis and Forecasts, 2018 – 2026

9.1.

Overview

9.1.1.

North America

Investment Casting Market Revenue (US$ Mn)

9.2.

North America

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

9.2.1.

Solid Mould

9.2.2.

Ceramic Shell

Mould

9.3.

North America

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

9.3.1.

Superalloys

9.3.2.

Steels

9.3.3.

Aluminium Alloy

Castings

9.3.4.

Titanium Alloy

Castings

9.3.5.

Others (brass,

glass)

9.4.

North America

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

9.4.1.

Filled Pattern

Waxes

9.4.2.

Non-filled

Pattern Waxes

9.4.3.

Runner Waxes

9.4.4.

Water-soluble

Waxes

9.4.5.

Repair Waxes

9.4.6.

Sticky Waxes

9.5.

North America

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

9.5.1.

Automotive

9.5.2.

Aerospace and

Military

9.5.3.

Engineering

Machinery

9.5.4.

General

Industrial Machinery

9.5.5.

Medical

9.6.

North America

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Country

9.6.1.

U.S.

9.6.1.1.

U.S. Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

9.6.1.1.1.

Solid Mould

9.6.1.1.2.

Ceramic Shell

Mould

9.6.1.2.

U.S. Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

9.6.1.2.1.

Superalloys

9.6.1.2.2.

Steels

9.6.1.2.3.

Aluminium Alloy

Castings

9.6.1.2.4.

Titanium Alloy

Castings

9.6.1.2.5.

Others (brass,

glass)

9.6.1.3.

U.S. Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

9.6.1.3.1.

Filled Pattern

Waxes

9.6.1.3.2.

Non-filled

Pattern Waxes

9.6.1.3.3.

Runner Waxes

9.6.1.3.4.

Water-soluble Waxes

9.6.1.3.5.

Repair Waxes

9.6.1.3.6.

Sticky Waxes

9.6.1.4.

U.S. Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Application

9.6.1.4.1.

Automotive

9.6.1.4.2.

Aerospace and

Military

9.6.1.4.3.

Engineering

Machinery

9.6.1.4.4.

General

Industrial Machinery

9.6.1.4.5.

Medical

9.6.2.

Rest of North

America

9.6.2.1.

Rest of North

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process

Type

9.6.2.1.1.

Solid Mould

9.6.2.1.2.

Ceramic Shell

Mould

9.6.2.2.

Rest of North

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material

Type

9.6.2.2.1.

Superalloys

9.6.2.2.2.

Steels

9.6.2.2.3.

Aluminium Alloy

Castings

9.6.2.2.4.

Titanium Alloy Castings

9.6.2.2.5.

Others (brass,

glass)

9.6.2.3.

Rest of North

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

9.6.2.3.1.

Filled Pattern

Waxes

9.6.2.3.2.

Non-filled

Pattern Waxes

9.6.2.3.3.

Runner Waxes

9.6.2.3.4.

Water-soluble

Waxes

9.6.2.3.5.

Repair Waxes

9.6.2.3.6.

Sticky Waxes

9.6.2.4.

Rest of North

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By

Application

9.6.2.4.1.

Automotive

9.6.2.4.2.

Aerospace and

Military

9.6.2.4.3.

Engineering

Machinery

9.6.2.4.4.

General

Industrial Machinery

9.6.2.4.5.

Medical

9.7.

Key Segment for

Channeling Investments

9.7.1.

By Country

9.7.2.

By Process Type

9.7.3.

By Material

Type

9.7.4.

By Wax Type

9.7.5.

By Application

10. Europe

Investment Casting Market Analysis and Forecasts, 2018 – 2026

10.1. Overview

10.1.1. Europe Investment Casting Market Revenue (US$

Mn)

10.2. Europe Investment Casting Market Revenue (US$

Mn) and Forecasts, By Process Type

10.2.1. Solid Mould

10.2.2. Ceramic Shell Mould

10.3. Europe Investment Casting Market Revenue (US$

Mn) and Forecasts, By Material Type

10.3.1. Superalloys

10.3.2. Steels

10.3.3. Aluminium Alloy Castings

10.3.4. Titanium Alloy Castings

10.3.5. Others (brass, glass)

10.4. Europe Investment Casting Market Revenue (US$

Mn) and Forecasts, By Wax Type

10.4.1. Filled Pattern Waxes

10.4.2. Non-filled Pattern Waxes

10.4.3. Runner Waxes

10.4.4. Water-soluble Waxes

10.4.5. Repair Waxes

10.4.6. Sticky Waxes

10.5. Europe Investment Casting Market Revenue (US$

Mn) and Forecasts, By Application

10.5.1. Automotive

10.5.2. Aerospace and Military

10.5.3. Engineering Machinery

10.5.4. General Industrial Machinery

10.5.5. Medical

10.6. Europe Investment Casting Market Revenue (US$

Mn) and Forecasts, By Country

10.6.1. France

10.6.1.1.

France

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.1.1.1.

Solid Mould

10.6.1.1.2.

Ceramic Shell

Mould

10.6.1.2.

France

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.1.2.1.

Superalloys

10.6.1.2.2.

Steels

10.6.1.2.3.

Aluminium Alloy

Castings

10.6.1.2.4.

Titanium Alloy

Castings

10.6.1.2.5.

Others (brass,

glass)

10.6.1.3.

France

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.1.3.1.

Filled Pattern

Waxes

10.6.1.3.2.

Non-filled

Pattern Waxes

10.6.1.3.3.

Runner Waxes

10.6.1.3.4.

Water-soluble

Waxes

10.6.1.3.5.

Repair Waxes

10.6.1.3.6.

Sticky Waxes

10.6.1.4.

France

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.1.4.1.

Automotive

10.6.1.4.2.

Aerospace and

Military

10.6.1.4.3.

Engineering

Machinery

10.6.1.4.4.

General

Industrial Machinery

10.6.1.4.5.

Medical

10.6.2. The UK

10.6.2.1.

The UK Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.2.1.1.

Solid Mould

10.6.2.1.2.

Ceramic Shell

Mould

10.6.2.2.

The UK

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.2.2.1.

Superalloys

10.6.2.2.2.

Steels

10.6.2.2.3.

Aluminium Alloy

Castings

10.6.2.2.4.

Titanium Alloy

Castings

10.6.2.2.5.

Others (brass,

glass)

10.6.2.3.

The UK

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.2.3.1.

Filled Pattern

Waxes

10.6.2.3.2.

Non-filled

Pattern Waxes

10.6.2.3.3.

Runner Waxes

10.6.2.3.4.

Water-soluble

Waxes

10.6.2.3.5.

Repair Waxes

10.6.2.3.6.

Sticky Waxes

10.6.2.4.

The UK

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.2.4.1.

Automotive

10.6.2.4.2.

Aerospace and

Military

10.6.2.4.3.

Engineering

Machinery

10.6.2.4.4.

General

Industrial Machinery

10.6.2.4.5.

Medical

10.6.3. Spain

10.6.3.1.

Spain

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.3.1.1.

Solid Mould

10.6.3.1.2.

Ceramic Shell

Mould

10.6.3.2.

Spain Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.3.2.1.

Superalloys

10.6.3.2.2.

Steels

10.6.3.2.3.

Aluminium Alloy

Castings

10.6.3.2.4.

Titanium Alloy

Castings

10.6.3.2.5.

Others (brass,

glass)

10.6.3.3.

Spain

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.3.3.1.

Filled Pattern

Waxes

10.6.3.3.2.

Non-filled

Pattern Waxes

10.6.3.3.3.

Runner Waxes

10.6.3.3.4.

Water-soluble

Waxes

10.6.3.3.5.

Repair Waxes

10.6.3.3.6.

Sticky Waxes

10.6.3.4.

Spain

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.3.4.1.

Automotive

10.6.3.4.2.

Aerospace and

Military

10.6.3.4.3.

Engineering

Machinery

10.6.3.4.4.

General

Industrial Machinery

10.6.3.4.5.

Medical

10.6.4. Germany

10.6.4.1.

Germany

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.4.1.1.

Solid Mould

10.6.4.1.2.

Ceramic Shell

Mould

10.6.4.2.

Germany

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.4.2.1.

Superalloys

10.6.4.2.2.

Steels

10.6.4.2.3.

Aluminium Alloy

Castings

10.6.4.2.4.

Titanium Alloy

Castings

10.6.4.2.5.

Others (brass,

glass)

10.6.4.3.

Germany

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.4.3.1.

Filled Pattern

Waxes

10.6.4.3.2.

Non-filled

Pattern Waxes

10.6.4.3.3.

Runner Waxes

10.6.4.3.4.

Water-soluble

Waxes

10.6.4.3.5.

Repair Waxes

10.6.4.3.6.

Sticky Waxes

10.6.4.4.

Germany

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.4.4.1.

Automotive

10.6.4.4.2.

Aerospace and

Military

10.6.4.4.3.

Engineering

Machinery

10.6.4.4.4.

General

Industrial Machinery

10.6.4.4.5.

Medical

10.6.5. Italy

10.6.5.1.

Italy

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.5.1.1.

Solid Mould

10.6.5.1.2.

Ceramic Shell

Mould

10.6.5.2.

Italy

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.5.2.1.

Superalloys

10.6.5.2.2.

Steels

10.6.5.2.3.

Aluminium Alloy

Castings

10.6.5.2.4.

Titanium Alloy

Castings

10.6.5.2.5.

Others (brass,

glass)

10.6.5.3.

Italy

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.5.3.1.

Filled Pattern

Waxes

10.6.5.3.2.

Non-filled

Pattern Waxes

10.6.5.3.3.

Runner Waxes

10.6.5.3.4.

Water-soluble

Waxes

10.6.5.3.5.

Repair Waxes

10.6.5.3.6.

Sticky Waxes

10.6.5.4.

Italy

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.5.4.1.

Automotive

10.6.5.4.2.

Aerospace and

Military

10.6.5.4.3.

Engineering

Machinery

10.6.5.4.4.

General Industrial

Machinery

10.6.5.4.5.

Medical

10.6.6. Rest of Europe

10.6.6.1.

Rest of Europe

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

10.6.6.1.1.

Solid Mould

10.6.6.1.2.

Ceramic Shell

Mould

10.6.6.2.

Rest of Europe

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

10.6.6.2.1.

Superalloys

10.6.6.2.2.

Steels

10.6.6.2.3.

Aluminium Alloy

Castings

10.6.6.2.4.

Titanium Alloy

Castings

10.6.6.2.5.

Others (brass,

glass)

10.6.6.3.

Rest of Europe

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

10.6.6.3.1.

Filled Pattern

Waxes

10.6.6.3.2.

Non-filled

Pattern Waxes

10.6.6.3.3.

Runner Waxes

10.6.6.3.4.

Water-soluble

Waxes

10.6.6.3.5.

Repair Waxes

10.6.6.3.6.

Sticky Waxes

10.6.6.4.

Rest of Europe

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

10.6.6.4.1.

Automotive

10.6.6.4.2.

Aerospace and

Military

10.6.6.4.3.

Engineering

Machinery

10.6.6.4.4.

General

Industrial Machinery

10.6.6.4.5.

Medical

10.7. Key Segment for Channeling Investments

10.7.1. By Country

10.7.2. By Process Type

10.7.3. By Material Type

10.7.4. By Wax Type

10.7.5. By Application

11. Asia

Pacific Investment Casting Market

Analysis and Forecasts, 2018 – 2026

11.1. Overview

11.1.1. Asia Pacific Investment Casting Market Revenue

(US$ Mn)

11.2. Asia Pacific Investment Casting Market Revenue (US$

Mn) and Forecasts, By Process Type

11.2.1. Solid Mould

11.2.2. Ceramic Shell Mould

11.3. Asia Pacific Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Material Type

11.3.1. Superalloys

11.3.2. Steels

11.3.3. Aluminium Alloy Castings

11.3.4. Titanium Alloy Castings

11.3.5. Others (brass, glass)

11.4. Asia Pacific Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Wax Type

11.4.1. Filled Pattern Waxes

11.4.2. Non-filled Pattern Waxes

11.4.3. Runner Waxes

11.4.4. Water-soluble Waxes

11.4.5. Repair Waxes

11.4.6. Sticky Waxes

11.5. Asia Pacific Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Application

11.5.1. Automotive

11.5.2. Aerospace and Military

11.5.3. Engineering Machinery

11.5.4. General Industrial Machinery

11.5.5. Medical

11.6. Asia Pacific Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Country

11.6.1. China

11.6.1.1.

China

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

11.6.1.1.1.

Solid Mould

11.6.1.1.2.

Ceramic Shell

Mould

11.6.1.2.

China

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

11.6.1.2.1.

Superalloys

11.6.1.2.2.

Steels

11.6.1.2.3.

Aluminium Alloy

Castings

11.6.1.2.4.

Titanium Alloy

Castings

11.6.1.2.5.

Others (brass,

glass)

11.6.1.3.

China

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

11.6.1.3.1.

Filled Pattern

Waxes

11.6.1.3.2.

Non-filled

Pattern Waxes

11.6.1.3.3.

Runner Waxes

11.6.1.3.4.

Water-soluble

Waxes

11.6.1.3.5.

Repair Waxes

11.6.1.3.6.

Sticky Waxes

11.6.1.4.

China

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

11.6.1.4.1.

Automotive

11.6.1.4.2.

Aerospace and

Military

11.6.1.4.3.

Engineering

Machinery

11.6.1.4.4.

General

Industrial Machinery

11.6.1.4.5.

Medical

11.6.2. Japan

11.6.2.1.

Japan

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

11.6.2.1.1.

Solid Mould

11.6.2.1.2.

Ceramic Shell

Mould

11.6.2.2.

Japan

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

11.6.2.2.1.

Superalloys

11.6.2.2.2.

Steels

11.6.2.2.3.

Aluminium Alloy

Castings

11.6.2.2.4.

Titanium Alloy

Castings

11.6.2.2.5.

Others (brass,

glass)

11.6.2.3.

Japan

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

11.6.2.3.1.

Filled Pattern

Waxes

11.6.2.3.2.

Non-filled

Pattern Waxes

11.6.2.3.3.

Runner Waxes

11.6.2.3.4.

Water-soluble

Waxes

11.6.2.3.5.

Repair Waxes

11.6.2.3.6.

Sticky Waxes

11.6.2.4.

Japan

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

11.6.2.4.1.

Automotive

11.6.2.4.2.

Aerospace and

Military

11.6.2.4.3.

Engineering

Machinery

11.6.2.4.4.

General

Industrial Machinery

11.6.2.4.5.

Medical

11.6.3. India

11.6.3.1.

India

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

11.6.3.1.1.

Solid Mould

11.6.3.1.2.

Ceramic Shell

Mould

11.6.3.2.

India

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

11.6.3.2.1.

Superalloys

11.6.3.2.2.

Steels

11.6.3.2.3.

Aluminium Alloy

Castings

11.6.3.2.4.

Titanium Alloy

Castings

11.6.3.2.5.

Others (brass,

glass)

11.6.3.3.

India Investment

Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

11.6.3.3.1.

Filled Pattern

Waxes

11.6.3.3.2.

Non-filled

Pattern Waxes

11.6.3.3.3.

Runner Waxes

11.6.3.3.4.

Water-soluble

Waxes

11.6.3.3.5.

Repair Waxes

11.6.3.3.6.

Sticky Waxes

11.6.3.4.

India

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

11.6.3.4.1.

Automotive

11.6.3.4.2.

Aerospace and

Military

11.6.3.4.3.

Engineering

Machinery

11.6.3.4.4.

General

Industrial Machinery

11.6.3.4.5.

Medical

11.6.4. Southeast Asia

11.6.4.1.

Southeast Asia

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

11.6.4.1.1.

Solid Mould

11.6.4.1.2.

Ceramic Shell

Mould

11.6.4.2.

Southeast Asia

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

11.6.4.2.1.

Superalloys

11.6.4.2.2.

Steels

11.6.4.2.3.

Aluminium Alloy

Castings

11.6.4.2.4.

Titanium Alloy

Castings

11.6.4.2.5.

Others (brass,

glass)

11.6.4.3.

Southeast Asia

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

11.6.4.3.1.

Filled Pattern

Waxes

11.6.4.3.2.

Non-filled

Pattern Waxes

11.6.4.3.3.

Runner Waxes

11.6.4.3.4.

Water-soluble

Waxes

11.6.4.3.5.

Repair Waxes

11.6.4.3.6.

Sticky Waxes

11.6.4.4.

Southeast Asia

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

11.6.4.4.1.

Automotive

11.6.4.4.2.

Aerospace and

Military

11.6.4.4.3.

Engineering

Machinery

11.6.4.4.4.

General

Industrial Machinery

11.6.4.4.5.

Medical

11.6.5. Rest of Asia Pacific

11.6.5.1.

Rest of Asia

Pacific Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process

Type

11.6.5.1.1.

Solid Mould

11.6.5.1.2.

Ceramic Shell

Mould

11.6.5.2.

Rest of Asia

Pacific Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material

Type

11.6.5.2.1.

Superalloys

11.6.5.2.2.

Steels

11.6.5.2.3.

Aluminium Alloy

Castings

11.6.5.2.4.

Titanium Alloy

Castings

11.6.5.2.5.

Others (brass,

glass)

11.6.5.3.

Rest of Asia

Pacific Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

11.6.5.3.1.

Filled Pattern

Waxes

11.6.5.3.2.

Non-filled

Pattern Waxes

11.6.5.3.3.

Runner Waxes

11.6.5.3.4.

Water-soluble

Waxes

11.6.5.3.5.

Repair Waxes

11.6.5.3.6.

Sticky Waxes

11.6.5.4.

Rest of Asia

Pacific Investment Casting Market Revenue (US$ Mn) and Forecasts, By

Application

11.6.5.4.1.

Automotive

11.6.5.4.2.

Aerospace and

Military

11.6.5.4.3.

Engineering

Machinery

11.6.5.4.4.

General

Industrial Machinery

11.6.5.4.5.

Medical

11.7. Key Segment for Channeling Investments

11.7.1. By Country

11.7.2. By Process Type

11.7.3. By Material Type

11.7.4. By Wax Type

11.7.5. By Application

12. Middle

East and Africa Investment Casting

Market Analysis and Forecasts, 2018 – 2026

12.1. Overview

12.1.1. Middle East and Africa Investment Casting Market

Revenue (US$ Mn)

12.2. Middle East and Africa Investment Casting Market

Revenue (US$ Mn) and Forecasts, By Process Type

12.2.1. Solid Mould

12.2.2. Ceramic Shell Mould

12.3. Middle East and Africa Investment Casting Market

Revenue (US$ Mn) and Forecasts, By Material Type

12.3.1. Superalloys

12.3.2. Steels

12.3.3. Aluminium Alloy Castings

12.3.4. Titanium Alloy Castings

12.3.5. Others (brass, glass)

12.4. Middle East and Africa Investment Casting Market

Revenue (US$ Mn) and Forecasts, By Wax Type

12.4.1. Filled Pattern Waxes

12.4.2. Non-filled Pattern Waxes

12.4.3. Runner Waxes

12.4.4. Water-soluble Waxes

12.4.5. Repair Waxes

12.4.6. Sticky Waxes

12.5. Middle East and Africa Investment Casting Market

Revenue (US$ Mn) and Forecasts, By Application

12.5.1. Automotive

12.5.2. Aerospace and Military

12.5.3. Engineering Machinery

12.5.4. General Industrial Machinery

12.5.5. Medical

12.6. Middle East and Africa Investment Casting Market

Revenue (US$ Mn) and Forecasts, By Country

12.6.1. GCC Countries

12.6.1.1.

GCC Countries

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

12.6.1.1.1.

Solid Mould

12.6.1.1.2.

Ceramic Shell

Mould

12.6.1.2.

GCC Countries

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

12.6.1.2.1.

Superalloys

12.6.1.2.2.

Steels

12.6.1.2.3.

Aluminium Alloy

Castings

12.6.1.2.4.

Titanium Alloy

Castings

12.6.1.2.5.

Others (brass,

glass)

12.6.1.3.

GCC Countries

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

12.6.1.3.1.

Filled Pattern

Waxes

12.6.1.3.2.

Non-filled

Pattern Waxes

12.6.1.3.3.

Runner Waxes

12.6.1.3.4.

Water-soluble

Waxes

12.6.1.3.5.

Repair Waxes

12.6.1.3.6.

Sticky Waxes

12.6.1.4.

GCC Countries

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

12.6.1.4.1.

Automotive

12.6.1.4.2.

Aerospace and

Military

12.6.1.4.3.

Engineering

Machinery

12.6.1.4.4.

General

Industrial Machinery

12.6.1.4.5.

Medical

12.6.2. Southern Africa

12.6.2.1.

Southern Africa

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

12.6.2.1.1.

Solid Mould

12.6.2.1.2.

Ceramic Shell

Mould

12.6.2.2.

Southern Africa

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

12.6.2.2.1.

Superalloys

12.6.2.2.2.

Steels

12.6.2.2.3.

Aluminium Alloy

Castings

12.6.2.2.4.

Titanium Alloy

Castings

12.6.2.2.5.

Others (brass, glass)

12.6.2.3.

Southern Africa

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

12.6.2.3.1.

Filled Pattern

Waxes

12.6.2.3.2.

Non-filled

Pattern Waxes

12.6.2.3.3.

Runner Waxes

12.6.2.3.4.

Water-soluble

Waxes

12.6.2.3.5.

Repair Waxes

12.6.2.3.6.

Sticky Waxes

12.6.2.4.

Southern Africa

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

12.6.2.4.1.

Automotive

12.6.2.4.2.

Aerospace and

Military

12.6.2.4.3.

Engineering

Machinery

12.6.2.4.4.

General

Industrial Machinery

12.6.2.4.5.

Medical

12.6.3. Rest of MEA

12.6.3.1.

Rest of MEA

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

12.6.3.1.1.

Solid Mould

12.6.3.1.2.

Ceramic Shell

Mould

12.6.3.2.

Rest of MEA

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

12.6.3.2.1.

Superalloys

12.6.3.2.2.

Steels

12.6.3.2.3.

Aluminium Alloy

Castings

12.6.3.2.4.

Titanium Alloy

Castings

12.6.3.2.5.

Others (brass,

glass)

12.6.3.3.

Rest of MEA

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

12.6.3.3.1.

Filled Pattern

Waxes

12.6.3.3.2.

Non-filled

Pattern Waxes

12.6.3.3.3.

Runner Waxes

12.6.3.3.4.

Water-soluble

Waxes

12.6.3.3.5.

Repair Waxes

12.6.3.3.6.

Sticky Waxes

12.6.3.4.

Rest of MEA

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

12.6.3.4.1.

Automotive

12.6.3.4.2.

Aerospace and

Military

12.6.3.4.3.

Engineering

Machinery

12.6.3.4.4.

General

Industrial Machinery

12.6.3.4.5.

Medical

12.7. Key Segment for Channeling Investments

12.7.1. By Country

12.7.2. By Process Type

12.7.3. By Material Type

12.7.4. By Wax Type

12.7.5. By Application

13. Latin

America Investment Casting Market Analysis and Forecasts, 2018 – 2026

13.1. Overview

13.1.1. Latin America Investment Casting Market Revenue

(US$ Mn)

13.2. Latin America Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Process Type

13.2.1. Solid Mould

13.2.2. Ceramic Shell Mould

13.3. Latin America Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Material Type

13.3.1. Superalloys

13.3.2. Steels

13.3.3. Aluminium Alloy Castings

13.3.4. Titanium Alloy Castings

13.3.5. Others (brass, glass)

13.4. Latin America Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Wax Type

13.4.1. Filled Pattern Waxes

13.4.2. Non-filled Pattern Waxes

13.4.3. Runner Waxes

13.4.4. Water-soluble Waxes

13.4.5. Repair Waxes

13.4.6. Sticky Waxes

13.5. Latin America Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Application

13.5.1. Automotive

13.5.2. Aerospace and Military

13.5.3. Engineering Machinery

13.5.4. General Industrial Machinery

13.5.5. Medical

13.6. Latin America Investment Casting Market Revenue

(US$ Mn) and Forecasts, By Country

13.6.1. Brazil

13.6.1.1.

Brazil

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process Type

13.6.1.1.1.

Solid Mould

13.6.1.1.2.

Ceramic Shell

Mould

13.6.1.2.

Brazil

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material Type

13.6.1.2.1.

Superalloys

13.6.1.2.2.

Steels

13.6.1.2.3.

Aluminium Alloy

Castings

13.6.1.2.4.

Titanium Alloy

Castings

13.6.1.2.5.

Others (brass,

glass)

13.6.1.3.

Brazil

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

13.6.1.3.1.

Filled Pattern

Waxes

13.6.1.3.2.

Non-filled

Pattern Waxes

13.6.1.3.3.

Runner Waxes

13.6.1.3.4.

Water-soluble

Waxes

13.6.1.3.5.

Repair Waxes

13.6.1.3.6.

Sticky Waxes

13.6.1.4.

Brazil

Investment Casting Market Revenue (US$ Mn) and Forecasts, By Application

13.6.1.4.1.

Automotive

13.6.1.4.2.

Aerospace and

Military

13.6.1.4.3.

Engineering

Machinery

13.6.1.4.4.

General

Industrial Machinery

13.6.1.4.5.

Medical

13.6.2. Rest of Latin America

13.6.2.1.

Rest of Latin

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Process

Type

13.6.2.1.1.

Solid Mould

13.6.2.1.2.

Ceramic Shell

Mould

13.6.2.2.

Rest of Latin

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Material

Type

13.6.2.2.1.

Superalloys

13.6.2.2.2.

Steels

13.6.2.2.3.

Aluminium Alloy

Castings

13.6.2.2.4.

Titanium Alloy

Castings

13.6.2.2.5.

Others (brass,

glass)

13.6.2.3.

Rest of Latin

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By Wax Type

13.6.2.3.1.

Filled Pattern

Waxes

13.6.2.3.2.

Non-filled

Pattern Waxes

13.6.2.3.3.

Runner Waxes

13.6.2.3.4.

Water-soluble

Waxes

13.6.2.3.5.

Repair Waxes

13.6.2.3.6.

Sticky Waxes

13.6.2.4.

Rest of Latin

America Investment Casting Market Revenue (US$ Mn) and Forecasts, By

Application

13.6.2.4.1.

Automotive

13.6.2.4.2.

Aerospace and

Military

13.6.2.4.3.

Engineering

Machinery

13.6.2.4.4.

General

Industrial Machinery

13.6.2.4.5.

Medical

13.7. Key Segment for Channeling Investments

13.7.1. By Country

13.7.2. By Process Type

13.7.3. By Material Type

13.7.4. By Wax Type

13.7.5. By Application

14. Competitive

Benchmarking

14.1. Player Positioning Analysis

14.2. Global Presence and Growth Strategies

15. Player

Profiles

15.1. ABB

15.1.1. Company Details

15.1.2. Company Overview

15.1.3. Product Offerings

15.1.4. Key Developments

15.1.5. Financial Analysis

15.1.6. SWOT Analysis

15.1.7. Business Strategies

15.2. Alcoa Corporation

15.2.1. Company Details

15.2.2. Company Overview

15.2.3. Product Offerings

15.2.4. Key Developments

15.2.5. Financial Analysis

15.2.6. SWOT Analysis

15.2.7. Business Strategies

15.3. Amtek Group

15.3.1. Company Details

15.3.2. Company Overview

15.3.3. Product Offerings

15.3.4. Key Developments

15.3.5. Financial Analysis

15.3.6. SWOT Analysis

15.3.7. Business Strategies

15.4. Aristo Cast Corporation

15.4.1. Company Details

15.4.2. Company Overview

15.4.3. Product Offerings

15.4.4. Key Developments

15.4.5. Financial Analysis

15.4.6. SWOT Analysis

15.4.7. Business Strategies

15.5. Bharat Forge Ltd.

15.5.1. Company Details

15.5.2. Company Overview

15.5.3. Product Offerings

15.5.4. Key Developments

15.5.5. Financial Analysis

15.5.6. SWOT Analysis

15.5.7. Business Strategies

15.6. CIREX

15.6.1. Company Details

15.6.2. Company Overview

15.6.3. Product Offerings

15.6.4. Key Developments

15.6.5. Financial Analysis

15.6.6. SWOT Analysis

15.6.7. Business Strategies

15.7. Doncasters Group Ltd

15.7.1. Company Details

15.7.2. Company Overview

15.7.3. Product Offerings

15.7.4. Key Developments

15.7.5. Financial Analysis

15.7.6. SWOT Analysis

15.7.7. Business Strategies

15.8. Georg Fischer Ltd.

15.8.1. Company Details

15.8.2. Company Overview

15.8.3. Product Offerings

15.8.4. Key Developments

15.8.5. Financial Analysis

15.8.6. SWOT Analysis

15.8.7. Business Strategies

15.9. MetalTek International

15.9.1. Company Details

15.9.2. Company Overview

15.9.3. Product Offerings

15.9.4. Key Developments

15.9.5. Financial Analysis

15.9.6. SWOT Analysis

15.9.7. Business Strategies

15.10. Milwaukee Precision Casting, Inc.

15.10.1.

Company Details

15.10.2.

Company

Overview

15.10.3.

Product

Offerings

15.10.4.

Key

Developments

15.10.5.

Financial

Analysis

15.10.6.

SWOT Analysis

15.10.7.

Business

Strategies

15.11. Nova Technocast

15.11.1.

Company Details

15.11.2.

Company

Overview

15.11.3.

Product

Offerings

15.11.4.

Key

Developments

15.11.5.

Financial

Analysis

15.11.6.

SWOT Analysis

15.11.7.

Business

Strategies

15.12. Precision Castparts Corp

15.12.1.

Company Details

15.12.2.

Company

Overview

15.12.3.

Product

Offerings

15.12.4.

Key

Developments

15.12.5.

Financial

Analysis

15.12.6.

SWOT Analysis

15.12.7.

Business

Strategies

15.13. RLM Industries, Inc.

15.13.1.

Company Details

15.13.2.

Company

Overview

15.13.3.

Product

Offerings

15.13.4.

Key

Developments

15.13.5.

Financial

Analysis

15.13.6.

SWOT Analysis

15.13.7.

Business

Strategies

15.14. Signicast

15.14.1.

Company Details

15.14.2.

Company

Overview

15.14.3.

Product

Offerings

15.14.4.

Key

Developments

15.14.5.

Financial

Analysis

15.14.6.

SWOT Analysis

15.14.7.

Business

Strategies

15.15. Solidscape Inc.

15.15.1.

Company Details

15.15.2.

Company

Overview

15.15.3.

Product

Offerings

15.15.4.

Key

Developments

15.15.5.

Financial

Analysis

15.15.6.

SWOT Analysis

15.15.7.

Business

Strategies

15.16. The Anchor Danly Company

15.16.1.

Company Details

15.16.2.

Company

Overview

15.16.3.

Product

Offerings

15.16.4.

Key Developments

15.16.5.

Financial

Analysis

15.16.6.

SWOT Analysis

15.16.7.

Business

Strategies

15.17. THOMPSON INVESTMENT CASTING

15.17.1.

Company Details

15.17.2.

Company

Overview

15.17.3.

Product

Offerings

15.17.4.

Key

Developments

15.17.5.

Financial

Analysis

15.17.6.

SWOT Analysis

15.17.7.

Business

Strategies

15.18. ThyssenKrupp AG

15.18.1.

Company Details

15.18.2.

Company

Overview

15.18.3.

Product

Offerings

15.18.4.

Key

Developments

15.18.5.

Financial

Analysis

15.18.6.

SWOT Analysis

15.18.7.

Business

Strategies

15.19. ZOLLERN GmbH & Co. KG.

15.19.1.

Company Details

15.19.2.

Company

Overview

15.19.3.

Product

Offerings

15.19.4.

Key

Developments

15.19.5.

Financial

Analysis

15.19.6.

SWOT Analysis

15.19.7.

Business

Strategies

Note: This ToC is

tentative and can be changed according to the research study conducted during

the course of report completion.

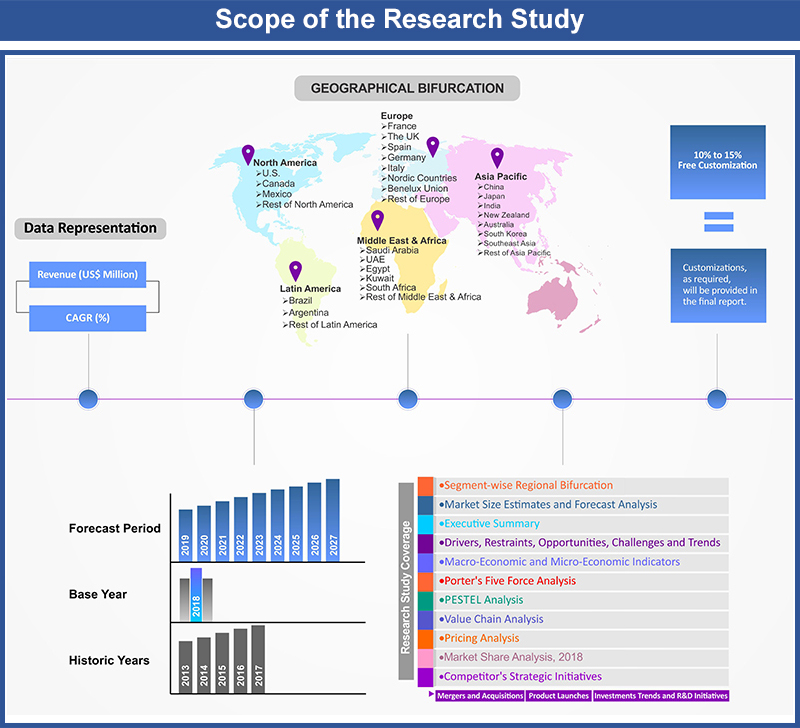

At Absolute Markets Insights, we are engaged in building both global as well as country specific reports. As a result, the approach taken for deriving the estimation and forecast for a specific country is a bit unique and different in comparison to the global research studies. In this case, we not only study the concerned market factors & trends prevailing in a particular country (from secondary research) but we also tend to calculate the actual market size & forecast from the revenue generated from the market participants involved in manufacturing or distributing the any concerned product. These companies can also be service providers. For analyzing any country specifically, we do consider the growth factors prevailing under the states/cities/county for the same. For instance, if we are analyzing an industry specific to United States, we primarily need to study about the states present under the same(where the product/service has the highest growth). Similar analysis will be followed by other countries. Our scope of the report changes with different markets.

Our research study is mainly implement through a mix of both secondary and primary research. Various sources such as industry magazines, trade journals, and government websites and trade associations are reviewed for gathering precise data. Primary interviews are conducted to validate the market size derived from secondary research. Industry experts, major manufacturers and distributors are contacted for further validation purpose on the current market penetration and growth trends.

Prominent participants in our primary research process include:

- Key Opinion Leaders namely the CEOs, CSOs, VPs, purchasing managers, amongst others

- Research and development participants, distributors/suppliers and subject matter experts

Secondary Research includes data extracted from paid data sources:

- Reuters

- Factiva

- Bloomberg

- One Source

- Hoovers

Research Methodology

Key Inclusions

Why Absolute Markets Insights?

An effective strategy is the entity that influences a business to stand out of the crowd. An organization with a phenomenal strategy for success dependably has the edge over the rivals in the market. It offers the organizations a head start in planning their strategy. Absolute Market Insights is the new initiation in the industry that will furnish you with the lead your business needs. Absolute Market Insights is the best destination for your business intelligence and analytical solutions; essentially because our qualitative and quantitative sources of information are competent to give one-stop solutions. We inventively combine qualitative and quantitative research in accurate proportions to have the best report, which not only gives the most recent insights but also assists you to grow.